Lucy Clay Brand Polymer Cane Slicer Demo And Review

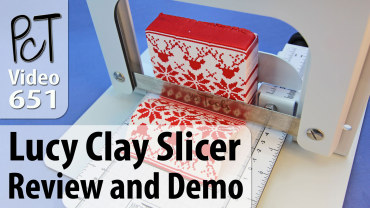

Video #651: This is a polymer clay cane slicer on the grandest of scales… it is a really beautiful, top-of-the-line machine!

More...

IN THIS POST: — lucy clay slicer — lucy clay tools — lc slicer — lucy clay — cane slicer — cane slicing tool — cane slice — cane — canes — millefiori — cane work — demo — review — (Topics marked with an asterisk* are discussed in the Comments Section below).

Today I’m going to show you the LC Slicer made by Lucy Clay Tools.

This is a cane slicer on the grandest of scales… it is a really beautiful machine!

We have talked about the Lucy Clay Tools before… this company makes very high quality tools that are built to be sturdy and strong.

This machine was sent to me by Diane Bruce of VanIslandJewels on Etsy. She is a Canadian Distributor that ships worldwide. A direct link to Diane’s Etsy Shop is right below today’s video on this page. (ADDENDUM: Diane Bruce is no longer a distributor for the Lucy Clay Products, but I have added a link to the Lucy Clay Products on Amazon. She does have some wonderful polymer clay tools and supplies in her Etsy Shop, though, so do check her out.)

This tool was designed to slice polymer clay canes whether they are small or large, square, round or pretty much any shape and size you would make.

In the video, I show you how the slicer works.

The LC Slicer ships disassembled. It took me about an hour to put it all together.

The replaceable blade is incredibly sharp and stiff, and it cuts through even large older canes with ease.

Then moving bottom plate advances the cane forward in micro increments for paper thin or very thick, and perfectly even slices.

One improvement I would like to see is a quick release for the screw in the base, so that you could adjust the plate back and forth quicker, depending on the length of your cane.

The first slice is never perfect because you have to square up the cane first.

This machine is not cheap… like a top of the line Cadillac or Mercedes… but it is so beautifully made and the slices are so perfect that it is worth every penny.

It sliced through my large Christmas Sweater Cane with ease… a cane that was near impossible to (nicely) cut by hand.

This tool will not be in everybody’s price range, but if you work with polymer clay professionally or just really love having the best tools… it is a beautiful machine, and you will want to check it out!

00:00:03 –> 00:00:07 Hi guys, its Cindy Lietz, your Polymer Clay Tutor, and today’s PcT Product Demo, we are

00:00:07 –> 00:00:14 talking about the LC Slicer made by Lucy Clay Tools.

00:00:14 –> 00:00:21 Now this is a cane slicer on the grandest scale, it’s a really beautiful machine, I’ll

00:00:21 –> 00:00:24 show you a little bit about it in a second.

00:00:24 –> 00:00:31 Now, we’ve talked about the Lucy Clay Tools before, and they make very high end tools

00:00:31 –> 00:00:34 that are strong and built really well.

00:00:34 –> 00:00:45 This one was sent to me by Diane Bruce of Van Island Jewels on Etsy.com, and she is

00:00:45 –> 00:00:51 our Canadian distributor, but she ships worldwide and you’ll wanna check her out.

00:00:51 –> 00:00:58 But this slicer is really neat, it’s for slicing Polymer Clay canes whether they are small,

00:00:58 –> 00:01:10 little square canes or round canes, and it will also do really large canes like this

00:01:10 –> 00:01:14 Sweater…Christmas Sweater cane that we did back a few months ago.

00:01:14 –> 00:01:21 Now, let me just show you how this slicer works, and then I’ll show you a few more things,

00:01:21 –> 00:01:30 now, the…okay so, it’s got a platform at the bottom here that slides back and forth

00:01:30 –> 00:01:37 and you move that by turning the dial here, and so you can move your cane forward just

00:01:37 –> 00:01:44 little tiny bits at a time, or in larger sections and cut whatever slice that you want, so you

00:01:44 –> 00:01:46 have control over that.

00:01:46 –> 00:01:51 And then the arm here, there’s a little red dial…or a little red stopper at the back

00:01:51 –> 00:02:01 here that you can open up, and it’s just like a safety knob and it will keep the blade from

00:02:01 –> 00:02:06 moving, and then you can move it up and down here, and cut against the surface.

00:02:06 –> 00:02:12 Now this has got a protective little shield on it which I can take off right now, and

00:02:12 –> 00:02:20 I actually just store mine up here on the top of the machine so that I don’t lose it,

00:02:20 –> 00:02:28 and then we can cut our canes, now this is a super, super sharp blade and it’s very stiff,

00:02:28 –> 00:02:31 so it works beautifully for cutting through your canes.

00:02:31 –> 00:02:38 Now, it’s…like I said, it’s really well built, it’s strong, it came in a box that

00:02:38 –> 00:02:47 basically was all apart, I actually had to take about an hour to put together, and there

00:02:47 –> 00:02:55 was… you have to put the grid onto the plate, it’s like a big sticker you stick it on there,

00:02:55 –> 00:03:03 you have to attach…you have to bolt everything down, and it takes a bit of putting together,

00:03:03 –> 00:03:10 but there’s some instructions there and… that will help you figure it out, and you

00:03:10 –> 00:03:15 have to bolt it all together, it’s not very hard but it’s time consuming.

00:03:15 –> 00:03:21 Then what you do is you figure out the size of your cane, I’m gonna lock this… put the

00:03:21 –> 00:03:26 pin out and keep it up higher, so that I can have some room here to work and I’ll just

00:03:26 –> 00:03:33 put my cane in back against the plate, now I’ll need to move it out…I’m just gonna

00:03:33 –> 00:03:37 stick it down really well, I’m doing this more awkwardly than normal ‘cause I’m trying

00:03:37 –> 00:03:44 to keep my hands out of your view, then I’ve gotta figure out where I want to cut it.

00:03:44 –> 00:03:49 So I’m just going to figure out just where the first cut is gonna be, so I have to move

00:03:49 –> 00:03:56 it forward a bit, and that’s the only thing that I think, if I would wanna change anything,

00:03:56 –> 00:04:02 I’d want one of… like a quick release that could push it a big distance, you know, like

00:04:02 –> 00:04:06 when you use like a caulking gun and you can push that button down, and you can slide it

00:04:06 –> 00:04:11 right up and then you can squeeze the thing to get it to do the little steps, if they

00:04:11 –> 00:04:14 had something like that on here, that you didn’t have to crank it the whole time that

00:04:14 –> 00:04:17 would be nice, but other than that, this is good.

00:04:17 –> 00:04:22 So I’ve got it figured out where I can do my first slice, and then I’m just gonna push

00:04:22 –> 00:04:24 down and take a slice.

00:04:24 –> 00:04:35 Now, if I want to do a super thin slice, what I’m gonna do is just crank it forward, just

00:04:35 –> 00:04:47 one turn and then press it down, and look at how thin this is, this is like paper, paper

00:04:47 –> 00:04:56 thin, it just got a little tiny…here I’ve got like a bone folder here, and it is so,

00:04:56 –> 00:05:02 so thin and so perfectly even it’s just beautiful.

00:05:02 –> 00:05:09 Now this was a super old cane from my Tribal…I believe it was called a Tribal cane tutorial,

00:05:09 –> 00:05:16 and this cane has probably been sitting in my drawer for a couple of years now, at least,

00:05:16 –> 00:05:22 and it was slicing really beautifully, so I’m just gonna take one turn forward and slice

00:05:22 –> 00:05:30 it again, this is paper, paper thin…I’ll just use my fingers so I can pop it out of

00:05:30 –> 00:05:34 there, so you can see it works really beautifully.

00:05:34 –> 00:05:40 Now it works also on the round slices, on the larger ones, you have to adjust this one

00:05:40 –> 00:05:49 again to do this larger one, so let’s see…get this out of the way, and see…this is going

00:05:49 –> 00:05:58 to fit in here, and you can see it’ll even take the really, really large canes, and I’m

00:05:58 –> 00:06:03 gonna need to move that back a bit ‘cause that’ll be quite thick.

00:06:03 –> 00:06:10 So the first slice is always a little bit off, because you’ve got to get the whole thing

00:06:10 –> 00:06:15 square, so this may or may not be a perfect slice, but I wanted to show you how it’ll

00:06:15 –> 00:06:25 go right through a tall slice like that, so now what we can do… the first one has got

00:06:25 –> 00:06:33 a few holes in it ‘cause it wasn’t perfect, and then we’ll move it forward a couple, and

00:06:33 –> 00:06:41 then take another slice, all the way down, perfect.

00:06:41 –> 00:06:51 Now this machine is not cheap, but it’s sorta like one of those Cadillacs or Mercedes, it’s

00:06:51 –> 00:06:56 so beautifully made and so perfect…I mean look at that, a huge slice, I could not slice

00:06:56 –> 00:07:04 this very easily, certainly not by hand, I’ve tried, trust me I’ve had all sorts of things

00:07:04 –> 00:07:08 trying to figure out how to do it by hand and I couldn’t get it anywhere near that

00:07:08 –> 00:07:09 thin.

00:07:09 –> 00:07:14 But what I’m just trying to say is this won’t be in everybody’s price range, but if you

00:07:14 –> 00:07:20 do anything professionally or if you just really love to have the best tools, this is

00:07:20 –> 00:07:27 a beautiful machine and you’ll wanna check it out, it’s easy to use, it’s sturdy and

00:07:27 –> 00:07:29 does a beautiful, beautiful job.

00:07:29 –> 00:07:37 Alright, so I hope you enjoyed that, do make sure to go check out Diane Bruce’s site on

00:07:37 –> 00:07:41 Etsy, it’s called Van Island Jewels.

00:07:41 –> 00:07:48 And if you’ve got any other suggestions for future tutorials, make sure to leave those

00:07:48 –> 00:07:50 in the comment section below.

00:07:50 –> 00:07:54 And if you’ve got questions about Polymer Clay that you need answers for, there is a

00:07:54 –> 00:08:00 pretty good chance that we’ve already done a video on it, so make sure to make a good

00:08:00 –> 00:08:07 search and see if you can find what you need, if you don’t, then leave us a comment and…

00:08:07 –> 00:08:12 for a suggestion for future videos so that maybe we can make a video for you on that.

00:08:12 –> 00:08:15 Alright, so we’ll see you next time and bye for now.

Our goal is to translate these videos into as many languages as possible. If you are interested in helping with this initiative, then please do contact us and we will figure out a way to make it worth your while :)

Resource Links:

- Etsy: Diane Bruce of VanIslandJewels **

- Amazon: Lucy Clay Slicer **

- Related Video: Polymer Clay Tribal Cane Design Tutorial

- Related Video: Christmas Sweater Cane Polymer Clay Tutorial

- Related Video: Review of the Lucy Clay CzeXtruder

- Related Video: Lucy Clay Bead Baking Rack Demo

Resources marked with a double ** asterisk are affiliate links. If you click on them and decide to buy something, we may receive some compensation. This does not affect the price you pay in any way. What it does do, however, is helps us to continue providing free videos for you, here at the PcT website. Using our links to purchase your tools and supplies, is always greatly appreciated.

Sponsored Ads & Special Promotions

Shareable Images

To share this full blog post anywhere on the web that allows links in comments, here's a shortened url to copy and paste...

>> https://mypct.ca/v651 <<

Want to chat about today’s post? That’s what the comment section below is for. Scroll Down… We’d love to hear from you!

Or... if you would like to request a topic for a future post, here is the link to do that… PcT Suggestion Box

Are you going to try the Lucy Clay Pasta Machine and have you tried the Dream Machine? I would love to have a comparison from you!

LOL, adore enthusiasm! Hi, Anne. Glad to let you know most of these and many more have been meticulously trialed and blogged by Cindy. Please go to the upper right page and enter those terms into the search facility, and you’ll find a world of information….

As far as I know, Cindy does not yet have the Dream Machine, but, if you click on all the links and read the comments, you’ll find many members here have. I’d google search the DM and a member named Dixie, who has shared her experiences with hers.

Have fun, and all best.

Hi Anne, Jocelyn is right I do not have the Dream Machine but have tested several pasta machines in the past.

It would be good for the whole community for us to demo and compare all the available machines on the market including new Lucy Clay Machines. Hopefully we can make that happen soon.

Hi Anne, yes indeed I do have the Dream Machine. I won it in a Mothers Day Contest about 4 yrs ago. Before that I was using the cheap Sculpey pasta machine and was on my 2nd one. It’s like comparing a Cadillac to a Ford Escort. This past year I was finally able to get a motor and the difference is just amazing. However I have been in on the whole Lucy Clay Machines and am very impressed with the construction, ease of handling, new heights, ease of cleaning, able to use electric drill in place of motor etc; These people have carefully thought of everything. You also have 3 options for machines which puts it in line for every budget and space requirements. I have purchased their LC Slicer and their LC Extruder and you just can’t beat the quality of their products. If I had not gotten the Dream Machine I would seriously think about getting their Mamouth Clay Machine and I still might it all depends on finances. If I put purchasing a clay machine according to budgets and stability here is how I would list them. Lucy Clay 1) Dream Machine 2) Atlas 180 3) Atlas 150 4) Other Brands of Pasta machines 5) Sculpey Clay Machine 6). Now there are probably other brands of pasta machines that compare just as well as the Atlas 180 but I have never used them. I have always felt that as a beginner not wanting to spend much, try the Sculpey. From there you can decide if you like claying if you want to invest in a better tool. It is all going to boil down to what you want and what you expect and what you can afford. So that’s my story and I’m stickin’ to it. Wishing you all the best of luck and fun in your future clay endeavor. The Search feature at the top is a wonderful resource for any question you might have regarding to claying. If you can’t find it there, so many of us are always happy to answer your questions but try the Search function first.

Hi,

Curious to know your thoughts on whether it was worth getting the lucy clay chrome slicer or teal? Are you glad you did, reservations?

It’s a lot of money, but, I’m tired of getting paper cuts on my fingers/hands from using the blades when slicing my clay and screwing up on my slicing. I have the polyslicer and it’s good but there’s no way to measure the slices for uniform consistency.

thanks for your time and any replies.

my best,

Lori

Hi Lori, if you have the budget for the Lucy Clay Slicer I would definitely recommend it. It does a beautiful job and I can not imagine ever slicing a large cane, like the Christmas sweater cane in the demo, without this slicer. No regrets with this one.

Does anyone have suggestions on using the slicer for round canes? I’m very happy with it for square canes but I just got a bunch of flattened out slices from a round flower cane.

Krithika, in hot weather I put the cane in the fridge for ten minutes or so to cool it before slicing.

Also I use a block of translucent clay with a rounded dent in it to support the underside of the cane. Hope that helps :-)

Just saw a review on a different site for the Lucy Clay Slicer Angle Block, which:

a) allows you to set the cane further forward in the Lucy Clay Slicer, to be able to slice all of it

b) (the really exciting one to me) lets you angle the cane to be able to cut it obliquely. This doesn’t sound like such a big deal, because the slices don’t look that different when they come off of the slicer, but then the reviewer put the slices onto a backing sheet of clay and rolled it through the pasta roller, and the effect was COOL!! The reviewer also said that you could probably get different effects with canes such as mokugame, by being able to slice at an angle.

Once you and Doug get through this web site upgrade, Cindy, you might like to have a look at the Angle Block and play around with it to see what you can show us to do with it! :)

Will do Doreen, thanks for the suggestion!

Does anyone know the difference between the LC Slicer Chrome and the LC Slicer? I can see there is a handle on one of them and I guess one comes in colors. If I got one, I was wondering which one would be best.

Hi Lena,

The difference is the type and colour of handle on the front, and the colour of the back plate at the rear of the sliding portion.

The Chrome version is what Cindy has, and what I recently got too. I’ve also assembled one of the other (“plain”) LC Slicers, which in Australia are available in Teal and Magenta.

The handle on the non-Chrome models is a different shape. It’s a flat piece with a series of bends, folded over at the top where you grip it. That gripping area is much higher than on the Chrome model, being right at the top of the “guillotine”. The Chrome version has what is effectively a long cabinetry handle that sits perpendicular to the sliding guillotine at the point where it’s attached.

If it matters to you, you can wrap your hand all the way around the handle on the Chrome model, where on the others you can either use an underhand grip on the handle or press down from the top (there’s a nice wide surface to push down on), but you can’t use a closed grip, if you know what I mean.

The back plate is white on the Chrome model, and the same colour as the handle on the others.

I definitely like my Chrome one better than the Teal I assembled, but that’s mostly me liking visually-neutral things for my studio. They both seemed equally easy to “drive”.

The other difference is the price: the Chrome version is a bit more expensive!

I hope that helps.

Sue F

Thanks so much Sue! Great information.

The price difference isn’t that much when you are talking about spending the money. If I’m going to invest, I want to pick the right one for me. Not sure there is a wrong answer. It seems strange they are so similar yet enough to have two separate products. I’ll have to think about the handle and which one I would like best. Right now I am “air slicing” trying to think which one I would like best. LOL.

If anyone else has opinions on which they liked best – let me know!

Thanks,

Lena

(:

Just popped in to say thanks Cindy for showing all the new products and demonstrating how to use them. I would not even think of buying any new tool without watching one of your “how to” videos.

I used to be impatient to get my hands on the latest gizzmo, but now I watch and learn and wait for the MARKII version as by then the feedback collected by these clever people has been noted and improvments made.

When I think of all the new aids invented for PC addicts I look back to buying my first tissue blade and laugh at some of the weird and wonderful items I have used over the years, and still use some of them today. So my wish list grows ever longer, my PC space get for ever smaller. Now if somebody could invent a 120 minute hour, then that would be awesome….cheers xx……..

But then every year we would look twice as old! :)

I’ve been putting a small block of Plexiglass behind the cane so there’s no wastage at all.

I suppose a stack of playing cards taped together would do the same thing. Easier to make different sized buffers with playing cards so that might be a better way than the Plexiglass now I think about it. I’ll try it and let you know!

An unwrapped block of premo works too!

Sorry, you might have wanted this Creative Journey Studios link.

Love the Lucy Clay Tool cart system.

Cynthia, Just returned from a gathering in VA in which many tools for PC were discussed and pros and cons and fixes were offered for different ones.

The Lucy Clay Slicer, which I do own, has an inherent problem in that the sliding screw turned platform doesn’t allow for the whole cane to be sliced because it stops about 3/4 of an inch shy where the clay can no longer be pushed under the blade. Also the height of the opening for clays means there is a limit on the size of a cane that can be sliced.

Creative Journey Studios in Buford, GA has come up with a great fix for this in a kit that raises the slicer and adds a piece of acrylic that allows larger canes to be cut and every bit of a cane to be cut, no more annoying small ends of canes left after slicing. Ellen Prophater and Sue Sutherland have a great studio and the women are sharp when it comes to analyzing what works and how to make it work best. You should check it out.

Can you please give us a link to their website or kit they have?

I have been putting a unwrapped block of Premo one my back board and that handles the space issue. As far as slicing a bigger cane… I can’t imagine making one 4″ high and 6″ wide… that would be a lot of clay!

Hi there!

I bought both the slicer and extruder and have to say both are fantastic and service from Etsey site was great! Now I am waiting for ups to bring my Dream machine. I am a happy camper!

Cindy, I so love my LC Slicer. I bought it several months ago from the US Dealer and you are right, it is the Cadillac of the PC Slicers. I will admit I had a problem using it at first because all of my canes slices were off. A friend gave me a terrific tip and now I’m a pro at using it. When I first slice a cane I back it up against the plate like you did and took my first slice which of course is always off. But then I flipped the cane around and backed the perfect cut off end up to the stopper and cut a slice off from the other end. Ta-da! It sure solved my problem and I have done a new cane this way ever since The last slice is always perfect because I took that extra step at the beginning and I don’t have to remember which end I took my last cut from.

Thanks so much for showing this remarkable machine. I love your product videos even though I have already purchased what you are showing because they are so spot on and it just confirms that I made the right decision. :)

Agree Dixie, after the JoolTool, this little baby will be my next investment.

Hear a lot of folks commenting on how expensive it is, but, when you really look at the consistent thin slices you can obtain, versus other methods, you really do make up the cost in savings by being able to veneer stuff and use every single slice.

You can slice the canes thinner and use each and every slice until the end of the cane.

It is also remarkably well engineered and produced, all of the Lucy products are. Sometimes you have to spend more to get a better result. If you are in business with poly clay, her product line is the best.

Thanks for another good review, Cindy. My slicer arrived last week and I am delighted with it. It is beautifully engineered! It took me a while to assemble it as I began by using the instructions that came packed with it. If there is a drawback to it, it is the size of those instructions…. practically needed a magnifying lens to see them but you young ones probably won’t have that problem :-)

Krithika has already given the link to the YT video; I’d recommend watching it all the way though before you start assembly. I hadn’t done that and so I’d placed the slide sticker on the wrong way around. It does come off so not all was lost. I’m using a thin piece of polycarbonate sheet under the cutting area to protect the slide as I don’t think it’s cut-proof.

Cindy’s idea of a quick release is very good. Until they develop one we can always put a block of acrylic behind the canes to save winding in and out so much when changing canes. Also a taller block of acrylic (like a 4 x 4 inch) would help support taller canes like Cindy’s sweater cane.

Chrissie, I believe they are making some sort of add on that will support the large slab canes. It is currently in production and George (the owner of the company and Lucy’s father) said he would send me one when it becomes available. I think it attaches to the back plate. But we will see when it arrives. Thanks for your suggestions! I like the idea of adding an acrylic block behind… that would also help in slicing the canes closer to the ends.

Dear Chrissie,

thank you for your notes regarding to guide/user manual where is link to our supporting ytb channel as well as web site where you can find more relating info how to put all parts together.

So just reminding… YTB LCTools with all relating available videos.

Same links are also on our LC Store next to each item to provide the key info in electronic versions. Please ask your seller to update their eshop site as well.

Anyway we have been working on that right now (new web, better guides, etc.), follow our fb for fresh up-to-day info.

Wish you great time with polymer clay work.

George from Lucy Clay Tools

:-)

Many thanks for showing this, Cindy! I’ve been dying to get my hands on one to customise but was convinced to wait for a studio model to test first… only now I’m all impatient again!

Sue I think you would really appreciate the quality of this machine. It would suit your precise nature quite perfectly! :)

I received my slicer last week and so far I’m loving it! I’d like to add a word of caution though: while attaching the lower plate to the moving piece, I accidentally drove in one of the screws in too deep. The slicer still works fine but the top plate is at a weird angle the base one. I’d suggest a gentle touch when putting it together, especially since it’s such an expensive tool. There’s a video from Lucy tools on how to assemble the slicer that was very helpful for me.

Thank you for the video link Krithika. That will be quite helpful for everyone!

I saw your slicer sitting on the side lines of last weeks product demo video, to which I’m impatiently waiting for my order to arrive, hopefully today! I went nuts early last year on the Lucy Site and purchased the xl extruder and all the disks as well as this slicer. It is truly AWESOME!!

Sandy, I hope you enjoy your new machines! They are ally are wonderful!