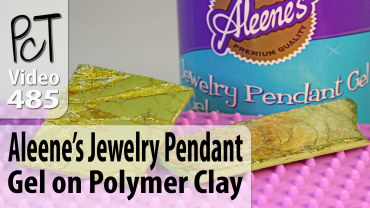

Using Aleene’s Jewelry Pendant Gel on Polymer Clay

Video #485: A very shiny coating for polymer pendants… gives the look of resin… only much softer.

IN THIS POST: — aleenes — jewelry pendant gel — resins — finishes — gloss — clear coat — glossy — shiny — glazes — resin — (Topics marked with an asterisk* are discussed in the Comments Section below).

Topics Covered In This Video:

- Aleene’s Jewelry Pendant Gel Product.

- Found in the glue section at Michael’s.

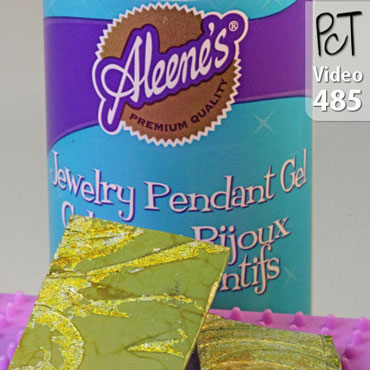

- Baked Premo Polymer Clay with Gold Leaf.

- Two coats of Aleene’s Pendant Gel.

- Test sample more than 1 month old with no adverse reactions.

- The coating is very glossy.

- Flexible. Does not crack, flake or peel when bent.

- The coating is fairly soft and not as hard as a resin coating.

- Will mark easily when fingernail is pressed into it.

- Deep surface marks do tend to recover and flatten back out, though.

- Would make a good clear liquid for miniature projects like the broth in a tiny bowl of soup with miniature polymer clay vegetables, or a miniature cup of coffee.

- Self Leveling.

- Gel is smooth but not runny.

- Dries crystal clear.

- 24 hour cure time between coats.

- Pop bubbles with pin.

- Odorless. Non-Toxic.

- Good substitute for resin for people with high sensitivities or for children.

- ADDENDUM: Unfortunately, it appears that this product is no longer being manufactured.

00:00:03 –> 00:00:08 Hi guys, its Cindy Lietz, your Polymer Clay Tutor, and today in the PcT Test Lab, we are

00:00:08 –> 00:00:14 testing Aleene’s Jewelry Pendant Gel on Polymer Clay.

00:00:14 –> 00:00:19 Now, as you know, I like to test different products on Polymer clay to see how they’re

00:00:19 –> 00:00:24 compatible, and this is an interesting one that I found at Michaels, I actually found

00:00:24 –> 00:00:29 it in the glue section, along with the Mod Podge and the other types of glues and things.

00:00:29 –> 00:00:35 And what it is, is a clear gel that you can add to different… well, it’s meant for

00:00:35 –> 00:00:42 pendants, but I’ve used it on a sample of baked Premo clay, I’ve got a little bit

00:00:42 –> 00:00:49 of Gold leaf on it and I thought I’d just test it out, now I’d put it on here back

00:00:49 –> 00:00:56 in December 29, 2013, so it’s been sitting on here for more than a month, and that’s

00:00:56 –> 00:00:59 just to see if it’s gonna be compatible over time.

00:00:59 –> 00:01:04 Now, there’s a few interesting things about it, first of all, it’s very, very shiny

00:01:04 –> 00:01:11 and it’s quite flexible, as you can see here, I’m bending my piece and I’m not

00:01:11 –> 00:01:17 seeing any cracking, or flaking or peeling, so that’s a good sign.

00:01:17 –> 00:01:21 It’s also compatible over the time that it’s been sitting on here, it hasn’t become

00:01:21 –> 00:01:25 sticky or anything like that.

00:01:25 –> 00:01:33 I’ve put two coats on it, and I noticed that it flows out fairly flat, I think if

00:01:33 –> 00:01:40 I wanted it to be really flat… especially on this dimensional piece here, I would have

00:01:40 –> 00:01:43 probably put 3 coats on, or a thicker coat in the first place.

00:01:43 –> 00:01:50 The thing I noticed about it is that the surface is a little bit soft, it’s not quite the

00:01:50 –> 00:01:57 same or as hard as a resin coating, if I press my fingernail into it, it will… like if

00:01:57 –> 00:02:02 I push really hard…I don’t know if the camera will pick up on it or not, but there

00:02:02 –> 00:02:07 is… it will leave a dent, though I have noticed if it sits for a while, it seems to

00:02:07 –> 00:02:14 kinda work its way out, so it doesn’t leave a really strong dent in there for very long,

00:02:14 –> 00:02:17 so it looks like it’ll wear quite well.

00:02:17 –> 00:02:23 I’m not positive whether it’ll make a perfect solution for a bead coating, just

00:02:23 –> 00:02:28 because it may get dented up or scratched up, but I’m gonna test that a little bit

00:02:28 –> 00:02:30 further and see how that comes along.

00:02:30 –> 00:02:36 But I’m excited about it, it seems like it would be a really great product to use

00:02:36 –> 00:02:41 for…for example, like if you’re making a miniature… maybe a little bowl of soup,

00:02:41 –> 00:02:46 and it has little pieces of miniature carrots and things in it, this would make a great

00:02:46 –> 00:02:52 clear liquid for something like that, or like a cup of coffee or something like that.

00:02:52 –> 00:02:57 I’d like to play with it a little bit more and see where we can use it, and see if it

00:02:57 –> 00:03:02 can be tinted or anything like that, but so far, it’s really neat.

00:03:02 –> 00:03:10 Now, I’ll just show you about it, it’s a…it comes out of the bottle here…it’s

00:03:10 –> 00:03:15 like a gel so it’s not super runny, and you can put it on quite thick, it’s fairly

00:03:15 –> 00:03:22 clear to start off with, I’ve just got a sample here, another piece of that same piece

00:03:22 –> 00:03:28 of baked clay with the Gold leaf on it, it’s not super runny so it doesn’t just run all

00:03:28 –> 00:03:33 over the place, I’ve got a little pin here where I can just pull it out to the edges

00:03:33 –> 00:03:40 of the piece, now, if it’s inside a bezel, it would fill the bezel quite nicely and easily.

00:03:40 –> 00:03:48 It takes about 24hrs to set up and be quite hard, if you put a thin coating on, you could

00:03:48 –> 00:03:55 put another coating on after the 24hrs, I wouldn’t rush putting another coating on,

00:03:55 –> 00:04:01 never do that with any …any finish that you’re doing, don’t rush and put a second

00:04:01 –> 00:04:02 coat on.

00:04:02 –> 00:04:08 Because sometimes, the first layer won’t have had a chance to set very well if you

00:04:08 –> 00:04:17 rush your second coating, and anyways, we’ve just… pulling it out to the edge, and it

00:04:17 –> 00:04:24 sets quite nicely, and like I said, it will flow out and level itself, if there’s any

00:04:24 –> 00:04:29 bubbles you can pop them with a pin, I wouldn’t use a lighter or anything, I haven’t tested

00:04:29 –> 00:04:34 that like you do on the other resins, to pop bubbles, I’m not sure if that’s gonna

00:04:34 –> 00:04:35 work or not.

00:04:35 –> 00:04:41 The nice thing about this product is there’s no smell, its non-toxic, so it would be a

00:04:41 –> 00:04:47 safe alternative to resin, especially if you’re working with someone with high sensitivities

00:04:47 –> 00:04:52 or children or something like that.I’m enjoying it and I would like to do more experimenting

00:04:52 –> 00:04:56 with it, and see what other kinds of things can be done with it.

00:04:56 –> 00:05:04 So I hope that was helpful for you, I’d love to hear from you, if you liked this video.

00:05:04 –> 00:05:08 And also, if you have suggestions for other products you’d like me to test, or techniques,

00:05:08 –> 00:05:13 or things that you’re having problems with, please leave those in the comment section

00:05:13 –> 00:05:14 below.

00:05:14 –> 00:05:16 So we’ll see you next time and bye for now.

Our goal is to translate these videos into as many languages as possible. If you are interested in helping with this initiative, then please do contact us and we will figure out a way to make it worth your while :)

Resource Links:

- Related Video: Shiny Polymer Clay Using Renaissance Wax

- Related Article: Polymer Clay Finishes – Which One Is Best?

- Related Article: Shiny Beads – 6 Tips for Getting a Gloss Finish

- Aleene's Original: Website

Resources marked with a double ** asterisk are affiliate links. If you click on them and decide to buy something, we may receive some compensation. This does not affect the price you pay in any way. What it does do, however, is helps us to continue providing free videos for you, here at the PcT website. Using our links to purchase your tools and supplies, is always greatly appreciated.

Sponsored Ads & Special Promotions

Shareable Images

To share this full blog post anywhere on the web that allows links in comments, here's a shortened url to copy and paste...

>> https://mypct.ca/v485 <<

Want to chat about today’s post? That’s what the comment section below is for. Scroll Down… We’d love to hear from you!

Or... if you would like to request a topic for a future post, here is the link to do that… PcT Suggestion Box

Thanks everyone for your product testing suggestions!! I will be adding them to the list for future videos. I appreciate your comments and support. Have a wonderful weekend!

How does this compare to Lisa Pavelka’s product? What about to DG3, or Diamond Glaze, or Glossy Accents, or Jaquard Pearl Ex Varnish (for PC among other things? I have all of these products but I do like using resin – especially ICE. Thanks for showing new products so we can find what works best for us and in different situations!

Hi, Cindy,

Just watched your video on using Aleen’s Jewelry Pendant Gel and felt inspired to relate, to you, the product I use for a very good shine on poly and also wood where I used it originally. I tried it about a year ago on several poly figures that I made and some small cabs that I have yet to mount or encircle with wire. It’s inexpensive, goes a very long way, and even after a year or so there’s absolutely no stickiness! Drum roll, please, (unless you’ve already addressed the product) it’s made by Minwax and its Water Based Polycrylic Protective Finish. Goes a long, long way and can be found at any hardware or paint store. Love your videos now that I’ve figured out how to access them!!! Cheers, Dotty, Bellevue, Wa.

Thanks for posting this! I work at Michaels and will probably pick some up soon.

I also use little-windows resin for my resin products, but am wondering if I dome that resin on top of my polymer pendants what will happen. I like their resin because its sold in small amounts, they have fabulous molds to use, its crystal clear and self leveling and they have a bunch of accessories. I have had many questions over the years about resin, and when I ask the company I usually get a quick response from the owner, which is nice.

How does this product handle heat? Have you tried baking it?

Dear Cindy.

Would it be possible for you to show how to apply those gold leaf in thin strips onto polymer clay surface?

Thank you,

Svetlana

Well that is something I will try.

Would you say it gives the same effect as Ranger’s glossy accents?

Hi Cindy,

I browsed your YouTube channel and blog but couldn’t find an answer to my question. I also watched your baking polymer clay video, it helped, but I still have a question.

I just started working with polymer clay. I have a craft oven that I bake my clay in. And I follow the directions on the packaging. My problem is that my clay turns out “bendable”. I’m trying to make pendants, the clay is approximately 1/4 inch thick when formed, I preheat my oven, bake for the said time & temp, but even after cooled, my clay is a bit soft and bendable. Not sure how bendable because I “chicken out” from bending it all the way or breaking it. I really don’t know what’s wrong, or what I’m doing wrong. Can you please explain to me what I should try to correct this problem?

Thanks a bunch!

Donna

Hi Donna, I just shot a video that will go out in the next couple of weeks that addresses this very thing. So stay tuned for that. But the short answer is, that it is normal for a properly baked piece of polymer clay to be bendy after baking, especially if it is thin. So no, you are not doing anything wrong!

i dip mine in cold water out of the oven and it hardens up nicely

Cindy, thank you so much for the experiment on Aleenes product gel. I have never heard of this one and I can see many alternate uses for it. So glad you are always on the look out for new items to try and send feedback to us. I will definitely grab a bottle of that the next time I’m at Michaels!