Is It Compatible With Polymer Clay? Always Test!

Video #375: And remember that testing for polymer compatibility issues does take time.

More...

IN THIS POST: — compatibility — vintaj — patina — inks — pymii — (Topics marked with an asterisk* are discussed in the Comments Section below).

Topics Covered In This Video:

- Just because someone says you can use something on polymer clay (i.e. paints, finishes, glazes, glues, etc.), doesn’t always mean it is true. Really, the only way to know for sure, is to test it yourself (or watch my videos ;-} or both).

- Some finishes seem fine at first, but will react with polymer clay over time.

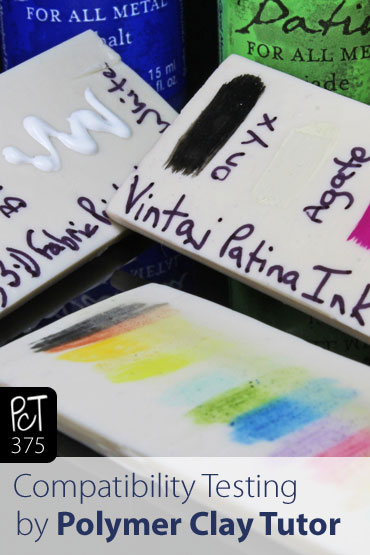

- Today’s video shows some of my test samples with the name of the product and date that my tests were started.

- Example of a product that got sticky after a few days – Vintaj Patina Inks on baked polymer clay (air dried, not heat set).

- Example of a sample sprayed with PYM II over three years ago, that still looks as good as new.

- Please don’t trust everything you see on the web.

- But you can always trust the information you learn here at the Polymer Clay Tutor, because I have tested it myself.

Have you used a product on polymer clay that seemed fine at first and then reacted over time? Please tell us about it in the comments section below, so that others can benefit from your discovery as well.

I look forward to hearing from you.

00:00:04 –> 00:00:08 Hi guys, its Cindy Lietz, your Polymer Clay Tutor, and in today’s Studio Tip, I just wanted

00:00:09 –> 00:00:16 to talk to you about pre-testing, and the importance of testing products to make sure

00:00:16 –> 00:00:20 that they’re actually Polymer Clay compatible.

00:00:20 –> 00:00:26 Just because somebody says, it is…you can use it on Polymer Clay, say out on the web

00:00:26 –> 00:00:31 somewhere somebody says that you can use something on Polymer Clay, that doesn’t mean that it’s

00:00:31 –> 00:00:37 necessarily true, and I always, always test first to find out if that’s really true, and

00:00:37 –> 00:00:40 the only way to do a really good test is to give it time.

00:00:40 –> 00:00:47 Now, I’m gonna show you…I’ve got these little test swatches of Polymer Clay sitting here

00:00:47 –> 00:00:52 with different types of products I’m testing on them.

00:00:52 –> 00:01:01 For example, I have some Scribble 3D Paint, scribbled onto here, and I wrote the date

00:01:01 –> 00:01:09 and what the product was, and I put what color it was, and this was back on April 5th, so

00:01:09 –> 00:01:17 not that long ago, but I can see that it may just work, I’m gonna give it more time though.

00:01:17 –> 00:01:23 And the reason why you need to give it more time is for this reason, recently there’s

00:01:23 –> 00:01:30 this new product on the market called Vintaj Patina, and it’s this awesome kinda cross

00:01:30 –> 00:01:39 between ink and paint, and it’s wonderful on metals, and I’ve used it quite a bit.

00:01:39 –> 00:01:43 But then I’ve seen some little tutorials on using it on Polymer Clay, so I thought I’d

00:01:43 –> 00:01:50 try it myself, now, to be fair, I only tried it on a baked piece of Polymer Clay, I have

00:01:50 –> 00:01:56 not tested it on raw clay yet, so maybe, if it’s baked in the oven it would work better,

00:01:56 –> 00:02:03 but here’s my test samples here, and I put Vintaj Patina inks on there April 5th, and

00:02:03 –> 00:02:10 I wrote the different names and put some different colors on here, and they dried really nicely

00:02:10 –> 00:02:14 and they’re really tough, like if I try to scratch on them, they don’t come off, so I

00:02:14 –> 00:02:16 thought that would be great.

00:02:16 –> 00:02:24 So I put some on this little test strip…little ring, just to wear around and kinda get a

00:02:24 –> 00:02:30 feel for what it… if it wore off at all, well, within a day or two, like I have it

00:02:30 –> 00:02:31 at my desk…

00:02:31 –> 00:02:37 I’m not wearing this beauty in public, within a day or two, it started to get really sticky

00:02:37 –> 00:02:43 and if you were to feel the sample, you can feel that it’s actually sticky, which means

00:02:43 –> 00:02:49 that it’s starting to react with the Polymer Clay, now I didn’t heat set this or bake it

00:02:49 –> 00:02:54 on there, I just let it air dry, so maybe you could get some different results if you

00:02:54 –> 00:02:57 heat set it, that I’ll also have to test.

00:02:57 –> 00:03:03 But, you know I’ve had different products that… like for example, nail polish, and

00:03:03 –> 00:03:08 people put nail polish on Polymer Clay all the time, and within a short period of time,

00:03:08 –> 00:03:15 it gets super sticky, and it’s… what’s happening is it dries on the surface, and then the whatever

00:03:15 –> 00:03:19 finish you put on top… you’ve got your clay underneath, the chemicals in the clay and

00:03:19 –> 00:03:24 the chemicals in the finish are… start working together against each other, and then it messes

00:03:24 –> 00:03:26 up the top finish.

00:03:26 –> 00:03:36 So a while ago, I had a company…a few years ago actually, who does a great product called

00:03:36 –> 00:03:42 PYM II, and it’s a finish that you can spray onto your scrapbooking projects and stuff

00:03:42 –> 00:03:47 like that, and they use it on metal and things, and they sent me a sample to try it on Polymer

00:03:47 –> 00:03:48 Clay.

00:03:48 –> 00:03:53 And here is my old test sample, I had a chunk of clay with some paint on the front side,

00:03:53 –> 00:03:59 a lace technique and some stuff on the back, here you can see I wrote test sample, March

00:03:59 –> 00:04:08 1st 2010, well this finish is beautiful years later, it’s tough, it’s not reactant and most

00:04:08 –> 00:04:14 sprays are reactant with Polymer Clay, so I know that over time if I sell this… something

00:04:14 –> 00:04:21 with the PYM on it, it’s not gonna break down and get weird and change.

00:04:21 –> 00:04:26 That is one of the biggest things that I think affects the quality down the road, you need

00:04:26 –> 00:04:31 to know when you’re listening to information on the web that the person that’s telling

00:04:31 –> 00:04:35 you actually has tested it, and they actually know what they’re talking about.

00:04:35 –> 00:04:41 And just because you did it last week and it looks really cool now doesn’t mean that

00:04:41 –> 00:04:47 3 weeks down the road it isn’t going to start doing something funky and start reacting,

00:04:47 –> 00:04:53 so just so you know, everything I do, you can trust, and I just want to let you know

00:04:53 –> 00:04:57 that, and later I’ll show you how to use these patinas, maybe I’ll do some more testing with

00:04:57 –> 00:05:03 the Vintaj inks ‘cause I do love them, and I’ve got, as you can see, lots of different

00:05:03 –> 00:05:07 products to show you after they’ve spent a little bit more time…knowing whether they

00:05:07 –> 00:05:09 work.

00:05:09 –> 00:05:14 So I hope you enjoyed that, please give it a thumbs up if that was helpful for you.

00:05:14 –> 00:05:15 And can you…

00:05:15 –> 00:05:23 my question of the day today is, have you had a product look okay at first and then

00:05:23 –> 00:05:24 react over time?

00:05:24 –> 00:05:30 Please tell us about that in the comment section below, so that we can let others know that

00:05:30 –> 00:05:32 it is a problem for you.

00:05:32 –> 00:05:35 Alright, so we’ll see you another time, bye for now.

Our goal is to translate these videos into as many languages as possible. If you are interested in helping with this initiative, then please do contact us and we will figure out a way to make it worth your while :)

Resource Links:

- Related Article: Preserve Your Memories PYM II On Polymer Clay

- Related Video: Plastic Types That Are Compatible With Polymer Clay

- Related Video: Gorilla Glue Is Compatible With Polymer Clay

- Related Video: Triple Thick Gloss Glaze Compatiblity

- Related Video: Test Tim Holtz Distress Embossing Powder on Polymer

- Related Video: Testing Tim Holtz Distress Ink And Stain on Polymer Clay

- Related Video: Using Sharpie Oil Based Paint Pens on Polymer Clay

Resources marked with a double ** asterisk are affiliate links. If you click on them and decide to buy something, we may receive some compensation. This does not affect the price you pay in any way. What it does do, however, is helps us to continue providing free videos for you, here at the PcT website. Using our links to purchase your tools and supplies, is always greatly appreciated.

Sponsored Ads & Special Promotions

Shareable Images

To share this full blog post anywhere on the web that allows links in comments, here's a shortened url to copy and paste...

>> https://mypct.ca/v375 <<

Want to chat about today’s post? That’s what the comment section below is for. Scroll Down… We’d love to hear from you!

Or... if you would like to request a topic for a future post, here is the link to do that… PcT Suggestion Box

Modpodge is not compatible with polymer clay. I used it to glue the clay to book surface and there is continuous movement in the book cover causing it to warp and delaminate.

Hi Cindy!

I was wondering after searching topics and not finding what I was looking for; Have you done a product test on adhesives for PC? My son would like to make knife handles, and we agreed that he could simply squish it onto and through the holes in the tang, but we were wondering about adhesives anyway. I Googled and asked the FB groups, but didn’t really find anything.

So, does Epoxy play well with PC? There are many types out there… but he likes Gorilla Epoxy…

Think it’s a worthy Tute?

Thanks!

Naomi

Hi Naomi, epoxy does play well with polymer clay from what I hear. I need to do more adhesive testing myself, since it is a worthy topic to be explored. Thanks for the suggestion!

Hello!! Love your videos! Very informative and easy to understand!

I was wondering if you’ve tested chalk pastels on your clay? I saw a tutorial where it was applied before baking to make a candle holder type project…

I’vve been burned before by products that react poorly to the clay…suck as modpodge clear glossy sealer…yeah it became sticky and my project was ruined. I also wanted to let you know about modpodge dimensional magic. Ive used it in bezels and it becomes cloudy after a few days. It failed big time.. so sad. It works good as a glue but i will never use it again in place of resin

thanks for reading!

Becky

Thank you for saving us from embarrassing failures! I frequently wonder about the validity of the info I find.

What a wonderful comment Marijana… thank you so much for sharing. Welcome to to PcT Community!

What I would like to point out after this video, is that you are raising standards for this beautiful art called “Polymer Clay”, and I really wanted to thank you for that. I’ve learned so much from your guest videos, but this one changed the hole view to my own work, making me decide not to waste time anymore. I am drawing the line here, and definitely joining PCT membership. I could not imagine better tutor than you.

Cindy – I wanted to say that love your video tutorials, your enthusiasm and your pep for life.

Thank you Barbara for saying that! I am really glad you are enjoying the videos! :D

Cindy, have you ever tested paints made for glass or metal on polymer clay. For example, permenamel, which is baked on in a 300degree oven for 30min. How do I tell if it is compatible? Thank you. Billie

Hi Billie, I haven’t tried Permenamel on polymer clay yet. I show have some around… just haven’t tried it yet. But I have tried DecoArt Ultra Gloss which is an oven bake paint for glass as well, and I do know it works beautifully on baked clay. Can’t remember if I tried it on raw clay that I baked though, so you would need to test that to be sure. Sounds like a good subject for a PcT Test Lab Segment!

Elaine, I’ll try to describe what PolyPaste is like: it comes in a very tiny jar and needs to be stirred, and is very thick and gluey, kinda like cold honey, but white. I usually use an Xacto knife with a flat tip to spread it around, and it’s sticky, so when I take some from the jar, it leaves a loooong strand between the knife and the jar. You need to be careful not to get it everywhere. What I often use it for is “grouting,” like if I have a flat surface and there’s a ding in it, I’ll mix it with some clay to make a paste, and then I’ll fill the ding in with the paste and then bake it and then sand down the “grout.”

Another thing I’ll do is to attach clay bails: I’ll take a baked piece and then attach some raw clay with the paste. Here’s the weird thing: I put some of the paste on the baked piece and then put the raw clay on the paste and make sure the raw and the baked pieces are attached firmly, and then I bake them. When I remove the piece from the oven, if I fiddle with it even a TINY bit, the bail will come loose and the paste looks like DRIED PASTE — you know, the kind of paste you use to paste paper together! You *really* need to leave it alone until it cools for it to be sturdy.

(So you’re thinking, “Bink, what on earth are you doing fiddling with a piece of hot clay for?” Because every now and then, I’ll think maybe the bail sticks out a little too far over here or there, and maybe I need to cut that teeny, tiny little bit off with an Xacto knife, and next thing I know, the hot PolyPaste is coming loose! Now I wait until it’s cool and sand it instead.)

It’s very, very matte, just like paper paste. After it’s cooked, anyway. When it’s still in the jar, it’s very glossy. And in the jar, it smells like Kato clay, though not as overpowering as the clay.

I hope that helps you to visualize it, and to understand why you can’t use it as an adhesive, except insofar as you can stick clay together with it.

Binky

Thanks Binky,

I can just imagine you fiddling with hot clay, so now I know NOT to when using PP. The grouting of “dings” sounds good though. I had a ding in one of my large French Barrettes and spent ages sanding it down to a smooth surface. By then it was nearly half the original thickness, but I had made it chunky anyway. Would sure have saved me all that effort using your method.

Looks like I’m going to have some sticky fun when it eventually arrives. One more question, can you plunge hot pieces in ice water when you have used PP or do you have to wait for them to cool naturally?……..cheers xx…………

Elaine, saving yourself from sanding things to half their thickness is *zactly* why you wanna make yourself some grout! Save your joints and your nails (and your projects)! ANYTHING that prevents sanding is wicked cool in my book!

I don’t believe I’ve ever plunged an item with hot PolyPaste into ice water, but I really don’t see why you can’t; after all, it’s largely clay, or rather, it was before you baked it. I’ll tell you what: I’m gonna be baking something this morning, so I’ll bake some scrap clay that I’ve PolyPasted, too, and drop it into ice water and report back.

Hi ladies – this is Awesome Information being handed out on this thread :)

been wanting poly paste for a while now

need to go ahead and move it up the wish list

also going to add that looping tool Shirley showed us in her video – could use it NOW as I’m making dangles for my MIL ‘s mother’s day gift :)

I was able to check off one item on my wish list (granted it was not on there as long as others) it’s called 1 Step Crimper by: beadbuddy And It Works – it’s nice to not worry about those dratted crimp tubes anymore :)

Binky and Sherry, plunged poly paste into plenty of ice cubes and water, and it held up great.

Hi Jocelyn

thanks for the update

our computer caught a bug – malware

froze it up good a hard :/

so one week and $100 later I’m back – Yay!!!

(So Very glad to be able to say ‘I didn’t do it’)ha ha

:)

Thanks Jocelyn,

DH very blue yesterday so wrote him a poem to cheer him up, but he choked up as I have never written one especially for him before. He phoned me later to send me some hugs!

………………………………….

So I was wondering, If I coated my ribbon, linen or other foreign material etc. both sides with bake and bond or other liquid clay and cured it I would then have a very thin veneer of polymer clay. As soon as I get my poly Paste I will give it a try. The reason is I want to embed between door and frame so it cannot be seen, then put fake decorative PC hinges on the door and frame, but with a gap large enough for it to open and close without catching.

I have also ordered some epoxy but as the ribbon hinges are sandwiched between two raw layers, the backing and faux wood veneer then cured I wasn’t sure if epoxy would work on raw clay? Hope I have explained this and you can see what I’m trying to do?

Yep Binky I’m stuck till my supplies arrive. I read loads of stuff about Poly Paste, but could never find it here in UK, or talked to anyone who has used it. but as Donna described it as an adhesive I just wondered about it’s properties?…………………cheers xx…………….

Here is a question for all you mad experimenters out there. I am waiting for my Poly Paste to arrive. I know it sticks raw to baked clay, but will it stick any of the following together to either raw or baked, Thin metal, leather, suede and the faux leather and suede, flexyplastic ties, linen covered in liquid clay? Has anyone tried it when it first came on the market and how long ago was this? As I am visiting the hospital every day (DH is very poorly) I have to ration my clay-play time so any answers from Cindy’s peeps would be great as have not got the time to spare for the usual testing of new products, although I love to put on my Lab Coat!!……………………..cheers xx…………………………….

Elaine, so sorry to hear your hub is in the hospital, prayers sent. Used Kato poly paste when it first came out, think about 10 years ago and loved it for clay on clay sticking. Not sure about how it works with other stuff.

Here’s a link and description from Donna Kato:

” Poly Paste

Poly Paste is a heavy-bodied adhesive that will not run when applied to vertical surfaces. Poly Paste can be used to attach cured and uncured pieces in any combination. Unlike other adhesives, Poly Paste fuses the two pieces together and creates a permanent bond.

Poly Paste will never dry out even if exposed to air. When cured at elevated temperatures, it will show no signs of degradation unlike other adhesives. Other ways to use Poly Paste include texturing, grouting, embossing, repairing cracks, and gilding when mixed with mica powders.

In order to take effect, Poly Paste must be cured. It may be cured between 265F (135C) and 325F (165C) for 10-30 minutes, depending on the polymer clay used and the recommended curing temperature.”

Here is another descriptive link.

I just googled “Kato’s Poly Paste” and a bunch of comments and information came up along with these above articles. Hope some of the info helps.

Elaine, PolyPaste is for gluing clay, either raw or baked, and not objects. For that, you’ll need to stick with (see what I did there?) cyanoacrylate or epoxy.

Binky

It’s been many years ago, too many to mention…that I had an unfortunate experience with a product. About a year after making and selling a miniature clay teddy bear line, I started making earrings with post backs, the surgical steel type with a flat round pad. Not knowing a lot about what glues to use on polymer clay, I used the thin liquid type of super glue (not sure which brand). After seeing the old commercial showing this glue as being strong enough to hold several pounds of steel, I felt it would work great. It did for a matter of months, maybe even a year, but then my appreciative relatives reluctantly told me that the backs were coming off. The super glue began to crack after time, a reaction that was unexpected after that many months. Also…yep there’s more, I had used a thick glaze, I think it was Joli-Glaze, but I am not positive, that after about a year was becoming sticky and the earrings that were in my relatives’ jewelry boxes (and mine!) were beginning to stick together. I learned my lesson the hard way but it taught me well. I only use tried and true products now on my polymer clay pieces. I truly appreciate people like Cindy who do tests so the rest of us can sleep easy at night! Thanks Cindy!

I do have a question for you Cindy, about your Vintaj Patina test. I also love the Patina paints on metal and did a TV jewelry demo featuring them this month actually, at if readers are interested.

I wondered if you added the Vintaj Patina glaze to the Patina paints that you used on polymer clay ring?

I know that the glaze thins the Patina paints making them more translucent on metal, so I imagine it may still react with clay. I have not tried them on clay yet (I use Premo also) to check if baking the Patina on the clay will prevent the stickiness. I am also glad that you explained in the video that a layer of a product can still react over time, when it is applied to the clay, even when a glaze/finish is applied over the top. Kudos!

Shirley

Hi Shirley, love the video btw! I WANT that looping tool. Would make the process of making dangles soo much faster!

No I did not use the glaze on the ring, though I did do a test strip of the glaze on that swatch I showed and it reacted the same. (I’m thinking that it is nearly the same product, minus the pigment, but that is just a guess.)

I should do some more tests, including heat setting and trying it on raw clay. But if you do some tests yourself, definitely come back here and let us know all about it!

Thanks for commenting!

Love the necklace, Shirley. And I want the tools, too, ALL OF THEM! They are so neat. Thanks for letting us know.

Wonderful video! Learned a lot, and it was fun to watch. Thanks for the share and all best…

To Jan,

Thanks so much for the information about your (no special finish) letter box and the items you sprayed with PYMII. It is so great when peeps chip in here with answers to questions I ponder about.

i thank you so very much for your reply although there was not a blue reply under your post so hope you pick up my thanks here. Gotta go as have 3 different couriers/postmen drop me off a slew of parcels. Ordered some summer clothes, new nightwear for DH (who is back in hosp, poor thing) and yipee my pen blanks and a tiny cordless hobby drill (mostly for my silver clay work)

It is lovely and sunny here in UK. I feel the need to buy a replacement bike after having my last two stolen.The local council have extended the cycle paths all over the town (thanks guys) Just going to get an ugly old fashioned one that hopefully the thieves will bypass and maybe fix a carrier to the back so Jessica (my jack Russel) will get to enjoy the open road!!!Well not road actually, the path I love used to be for walkers only and ran beside a brook away from roads. Now it has be opened up to cyclist.At one end is the local woods and the other end a beautiful park. So cannot wait to get out in the fresh air again………..cheers xx……….

You know, I SO appreciate this because I invest a lot in my pieces and, because of you, we can feel confident that that effort will be around for a long time. THANKS!

Cindy, great video on Vintaj, been waiting to see what you thought of the product.

I might be the only person who found the right clear nail polish to apply to Fimo, lol. One of the first projects with my eldest niece, we made the spiral cane, then a snake pot, then applied the slices to both sides of this pot. Fingerprints galore. Coated it several times inside and out, over 15 years ago, and even though the finish has yellowed, it is one creation I cherish most.

Agree that we so need to know products that work. But, never want us to stop experimenting. Who knew you could pull out a can of shoe polish and antique and buff a poly piece? It works. Who knew you could make a surface look like velvet by covering the clay with as much paprika and pepper as could be rolled in? Me.

Thanks to Cindy.

It may be the scardy cat in me but I have never used anything on pc that wasn’t specifically made for it or that one of the professionals didn’t recommend in books or tutorials. It just doesn’t feel intuitively right to me to pick up make-up, for instance, and use it on clay. There is so much quality variation in make-up lines and many have reactions on humans let alone on a substance such as clay. I always try to research each product thru several credible sources first. My personal guide is always that if I’m going to spend so much of my time, effort and creativity on a project, I want the product quality to stand up to that investment. There is the high cost of going cheap and there is the high cost of not doing your homework, too…of which I’ve done too often in my life and maybe that’s why sometimes I’m a scardy cat.

Love to All!

I have made tons of polymer necklaces in metal bezels with some beads as well (which I will say I haven’t perfected keeping them round when I pierce them.) I sprayed all of them and they were great… Until recently. They got the sticky disease. I first sealed them with Rust-Oleum Painters Touch (it said it bonds to plastic). Then when it got sticky I tried Krylon Make-it last over it.

Still sticky! So bad that it is leaving marks when they touch each other. Will the Varathane or any other sealant work well to coat and take away that stickiness?? Or are they trash now? Please tell me I can save them! They are mixed media and layered, not flat. I like the Matte look, but at this point I will take anything!

You can see them here if you don’t understand my crazy explanation :)

My other question. Can I also use Varathane for a varnish with fairy garden items being used outside? I am making one in my garden and hope to add a clay door, mushrooms etc. :)

Thank you so much!

Ivy

Oh Ivy they are so very pretty :)

I do hope someone knows of a way to save them !!

Thank you so much!!

Hi Ivy, your pendants are really beautiful, I looked at your FB page and you are quite talented. I love your work. I’m so sorry to hear about your problems glazing your items. If it were me I would probably try and remove all the old sticky spray with some 95% alcohol. It might take some time and effort but if you can save some of them, it would be worth it. What you don’t want to do is add more to whats already there. The stickyness indicates there is already some reaction going on between the clay and the sprays you used. You need to stop the action by using the alcohol. If you want to glaze it again you can use the Varathane Diamond Glaze but be sure the can says INTERIOR only. This is water based and works great with polymer clay. I have used it for 2 yrs. now and love it. I also use Sculpey Satin and Gloss glazes and don’t forget about the Ren Wax. For outside exposed to the weather I would prefer to use the PYMII spray myself but I am also testing Modge Podge’s new acrylic spray. Don’t know how that is going to work out yet. Maybe someone else knows of a good acrylic spray for outdoors that will work with PC. Good luck, hope this helps.

Agree 200% with Dixie Ann! I have learned the hard way with other types of crafts to NEVER add one product on top of another. And also to make sure to allow correct time in between coats if you don’t want sticky, gooey meltdown. When there’s a mess already it is time to stop, take a deep breath and rethink…LOL! Good luck and I hope you can save them.

Thank you Dixie! All of that REALLY helps! I will try to get all of those supplies ASAP! I will love you forever if this works haha.

I really appreciate the compliments! I have been doubting myself a lot lately, your compliments definitely encourage me to keep going! Thank you so so much!

Hi Ivy, it looks like the others got here to help you first, which is awesome! Their advice is solid. I love your work! It would be excellent (and most likely possible if you remove the old finish), if you could save them. Do come back and let us know how it goes for you. Remember that there are hundreds of articles and tutorials here and lots of helpful people, should you need anymore help. Good luck!

Update! I removed all of the glaze with 99% alcohol, it worked great! (Except a few areas I could not reach since there is so many layers and textures). It didn’t feel sticky where I could touch. Today I got the Varathane and I coated them with it and baked them at 215F for 5 mins (I wasn’t sure how long to bake and didnt want to over do it). So far it’s wonderful! I’m not big on glossy normally but this still looks nice. I read somewhere about dabbing wet Varathane with a makeup sponge to make it more matte. I think I might try that.

I think I might try to Varathane for the outside items as well, I went to order the PYMII and it was almost $25 for a can, that seems a little steep for something I will not get money back on. Maybe I will just add extra coats of the Varathane to make sure it is properly sealed? Hopefully once I post my finished garden on my fb page, someone will see and want to buy some items and then I will have a reason to order the PYMII lol.

I will keep updated if it gets sticky and how the Varathane works outside! :)

I will also update on my outside items on fb, PLEASE feel free to “like” it. :).

You are all so helpful and encouraging! Thank you all!

Cindy, thank you for all of your helpful posts, I can’t wait to read and learn more!

Ivy, sorry this is out of order, the reply boxes ran out, lol. Just finished exploring your etsy and FB sites, you are a very talented lady! So glad the 99% alcohol did the trick and your lovely dragons will be gorgeous.

Hi Ivy,

Loved your fairy door. I have two, sitting in the garden on test. The first I covered in ~~~~Renaissanc wax and the second in PYMII. they are in deep shade till the sun comes round then in full sunlight all afternoon. I’m gonna let them sit for a month to see how they stand up. When I water my pots I water them too. Not sure about snow though! Has anyone left their PC creations out in the snow? Last winter we had about 6 inches for a couple of weeks, so if I sell them at a Christmas market I want to put completly weatherproof and frost proof. Cannot test outside but might try putting one in the freezer for a time. any other suggestions?? Your work is beautiful, do not doubt yourself, you have real talent…………………..cheers xx…………………………

I made a letterbox sign about four years ago, it has been outside since in frost and rain (not much snow) and although the colour is a wee bit faded, it has held up well. There is no finish on it at all.

I made a few more and sprayed them with PYM11, they have lasted well too and the colour looks like new.

Well Cindy wrapped up in a box are the two purple dragons I made B.C. I think I used clear nail varnish on them but it was so long ago I might have used floor varnish .(They went sticky after a few weeks)

Now the poor little things are stuck to the tissue paper. One day I will rescue them, clean them off and use Renaissance Wax or PYMII as a finish.. One problem is, they have pearls embedded as well as other gem stones and beads. I am worried the pearls will dissolve if I use acetone or rubbing alcohol on them. Any suggestions before I take them out of their box?……..Cheers xx………

Oh dear Elaine, those poor little dragons! Maybe if they had a good scrub with an old tooth brush dipped in rubbing alcohol, they might be able to free themselves from that sticky layer of finish and paper? Hopefully. It would be a shame to lose them. I wouldn’t use acetone unless you were super careful and used a q-tip to control where it went. Acetone would most likely be too hard on the gems and pearls. But as long as the pearls are real and you tried to avoid them, the rubbing alcohol shouldn’t be too hard on them. Of course it would be important to test that first. Do let us know if you manage to save them.

Here is another example of mis-information. Transparencies run through an ink jet printer with a design printed on it. It tells you to take a piece of raw clay and brush it with Golden Gel and then lay the transparency on the clay and viola its suppose to transfer the design onto the clay. Nada, doesn’t work, makes a mess. I have come to rely so much on Cindys expertise and knowledge of working with different materials and polymer clay, she is the number 1 source I go to now rather than waste my time on others who profess to be experts in the field. With her I know my project will turn out the way it is suppose to and don’t have to worry about it not holding up later down the road. When you’ve had the best….why try the rest.

AMEN!

You are so right Dixie,I couldn’t have put it better myself. Cindy is the girl we can all trust to give us the right information. My first fairy door is hanging up, I tested it to destruction (well nearly) I used floristry ribbon ( that shiny waterproof stuff that you can curl nicely) It is really really strong..

Embedded between the frame and door. I used super glue, but there was nothing super in this glue as after opening and closing a hundred times the glue came unstuck from the ribbon Perhaps I should have tried another glue!. So now it is a door that stays shut, shame because I recycled a lovely Christmas card scene behind the door of a forest that looked like you could just step inside. Back to the drawing board, as now got some teeny tiny dollhouse hinges for my next few attempts and have to be perfect as my client is giving them as party bags for the birthday girl to hand out as the kids will all be dressed as fairies.Got to get it right by August. So no pressure!! !and you never know, if the kids like them they might tell their friends. ….cheers xx….

Thank you so much for saying that you three! I really appreciate it. I myself have been very frustrated with all the stuff out there with bad information on the web, in books and magazines. Sometimes it’s just missing stuff, but other times it is horrendously wrong. I just wish more people would test things for themselves before sharing it with the unknowing public. Oh well keeps me in business I guess!

Elaine your fairy doors sound wonderful! I chuckled out loud at the super-less super glue comment. You say things so cute! I’d love to see them when you get the mechanics worked out.

Well Cindy you say cute things too and sometimes when I watch your videos I have to chuckle as you get so excited to show us a” Cindy way” to do things, your tongue and brain have a tussle. Same with me! I’m the strong silent type!!. But I love all the umms etc. it shows you are a real person, and a very dear one to me. Thinking outside the box is always my way. There are loads of fairy doors out there. Most of the ones that open use “dollshouse hinges. OK I COULD do that but then I would think that’s a cop out!! (Do you have that expression in Canada?) Still think my floristery ribbon will work. Have about 15 rolls all different colors left over when I shut down my little Florists shop when I became ill. I make curly bits to decorate my gift boxes and bags, great stuff. So have sent off for Donna Kato’s Poly paste I love Donna and after reading all about poly paste at her site it sounds just what I am looking for….. so watch this space……….cheers xx………..

Yes ‘cop out’ is a phrase we use here in Canada all the time. I wonder what the origin of that one is? Any way, haven’t tried PolyPaste yet. Do tell us what you think when it arrives.

Sorry to hear that your hubby has been sick. Glad that he is coming home now though and I hope he recovers quickly. The swinging bench I read in one of your comments, sounds like a lovely place for you two to hang out while he recoups. Doug’s mom and dad used to have one of those swings. They are so peaceful and calming. I think he is really going to enjoy it! Make sure you have one of those fairy doors on a tree close by, so he can enjoy that too!

Elaine, a plea…..is there anyway that you could post a pic of that fairy door on Cindy’s PCT Facebook site? Would so love to see what is looks like, and someday, I want to make my own to put somewhere in my home.

Especially because this little gnome/fairy gateways, be they doors or windows, can be decorated in a Christmas motif, and become a family collectable.

Hope you are well and happy (and still in France).

Jocelyn

Last summer I found some paint that is used? for painting on glass at Micheal’s. It normally cost about $5 each but they were getting rid of it at a dollar something …so I picked out 4 or 5 colors AND remembering what you (Cindy L) said I did a test to cover one side of an ugly baked bead taped it to a piece of paper and dated it….ran across it a couple of weeks ago and ta-da it’s perfect. Thank you both for your trustworthy support to all of us for all these many years – Sherry

Hi Tantsherry

Here in the UK I visited my local print and copy centre. they were also selling off their glass paint really cheap in packs of five. So I took advantage of this special price. I think I will go back to buy another 5 colors. Haven’t got round to testing it yet but would be interested to know what brand you bought?….cheers xx….

Hi Elaine

it’s called pebeo All letters lower case and the 2 e’s have a straight line above them

below the pebeo word it says vitrea 160

also states bake at 325 degree but I did not do that and the test bead did great

should add that label says ‘transparent colour for glass water based’

I found 2 types one called ‘frosted’ the other ‘brilliant glossy’ both did great as described below

also before I stated my tumble sanding process – one set of the last beads I made I used this glass paint on raw trans and pearl clays and kind of twisted it around a bit to make a pleasing design in coin and rectangle shapes baked at normal temp for an hour – after using ren wax on them yesterday …. well I think they are beautiful and can’t wait to make more:)

Thanks Tantesherry

This was the brand I bought. Just wondering WHY they were so cheap and looks like they will not be stocked anymore?? So better head back down there to buy the rest of colors.

Many years ago before I discovered PC I used to make glass candle holders (votives), paint them with pebeo in all the bright colors. Added a stained glass type pattern using a mixture of grout, silver paint and glue

Rolled it out between wax paper (it was super sticky) Then let it semi harden over night, cut it into uniform strips (metal ruler and scalpel) No clay blades available then., Drew my design with black felt tip. Painted the lines with glue, stuck on my faux leaded pieces, waited over night then used black shoe polish on the “lead” to make it look authentic

What a palaver, as had to let the pebeo set for a few days when first put on glass as didn’t want it to come off when I rubbed off the black shoe polish. But at a Christmas market they flew off the stall as I had lit up a couple to show how pretty they looked. Now,thanks to Cindy and her glass ball mistletoe tutorial, I can revamp and refine this for the candle holders for winter. Thought I would put a row of stained glass angels with wings and gowns touching so no glue needed. Also with black and silve Premo, and no need for the boot polish I have the perfect faux lead and lastly my trusty clay extruder means I do not have to painstakensly (is that a word) measure and cut strips, I can just extrude them. So again a big thanks to all those wonderful companies that come up with all these tools to help us make the things we love……………….. cheers xx………….

Sorry the phone rang while I was editing this reply. The last line should have read. (and the biggest thanks to our wonderful tutor Cindy) who lets us run with her great ideas to have fun while we play….cheers. xx…… xx…….(doubled)

your angels sound beautiful Elaine

but the way you made faux stained glass was So Very Creative (and mad science-esqu) (?) lol

any way sending good thoughts and prayers your way hoping your DH is home to you soon-sherry

Polymer clay incompatibility hasn’t been a problem for me because I always test. (In fact, as a mad scientist type, I couldn’t *not* test, no matter who had provided advice! LOL)

I’ve found that products which are safe for one brand of polymer clay aren’t necessarily safe for other brands, which is possibly a factor in some of the apparently-misleading advice out on the internet (although there are also things out there that are just plain wrong).

Even products which are safe across all the brands I’ve tested sometimes behave differently on different clay brands — the PYM II that Cindy mentioned is a good example; it’s safe on all the polymer clay brands I’ve tried it on, but gives noticeably different finishes on Kato compared to Premo compared to Fimo — which is another reason I like to try things out for myself.

I’m sorry Sue I meant to comment the first time I read this but something came up and then I forgot! You make some excellent points!

I should mention (and I will try and remember next time) that I generally test products on Premo Sculpey clay since that is what I almost exclusively use, but there are chances that it may react to other brands of polymer clay quite differently. Like I always have encouraged my kids to think for themselves and not to blindly follow others, the same rule applies here as well. It is always best to test for yourself!

Sue you are definitely the Queen of thinking for yourself and doing your own experiments. I have learned so much from you over the years.

Some people don’t want to make the mistakes however, so it is beneficial to have a place where the information shared is the most trust-able as possible. It is nice for many people to have others like you and me who will do ‘the heavy lifting’ for them. It lessens the pain, expense and sometimes embarrassment from making their own mistakes trying to figure things out.

I am very grateful to have you here and sharing your testing with us all. I only have two hands and the more mad scientists we can add to the group, the more we can learn from each other. Thank you for being you!