Why Pasta Machines Leave Roller Lines On Polymer Clay

Video #641: And more importantly, how to end up with smooth sheets of clay that don’t show any roller lines at all!

More...

IN THIS POST: — pasta machine — roller lines — roller marks — gears — clay sheets — smooth — roller marks — atlas pasta machine — (Topics marked with an asterisk* are discussed in the Comments Section below).

Topics Covered In This Video:

- I’m going to show you how to avoid getting roller lines on your polymer clay from your pasta machine.

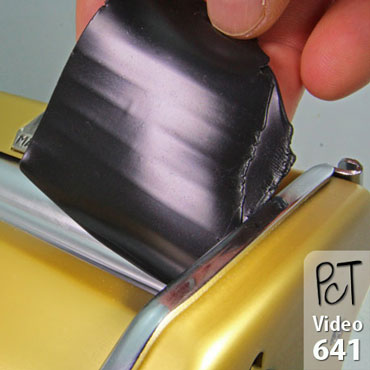

- Sometimes you will grab a chunk of polymer clay (mine happens to be a section of Sculpey Souffle clay in a Pumpkin color)… and roll it through your pasta machine at the thickest setting… and you’ll get these obvious lines running across the sheet that were caused by the pasta machine rollers.

- It doesn’t matter whether you have a beautiful pasta machine like this Atlas 150 Wellness Machine, or you have a lower end machine… those lines pretty much always show up when you are using the thickest setting.

- The reason is because of the gears on the rollers, and how they fit together at the different settings.

- The two rollers in a pasta machine turn when you roll your clay through.

- There are gears at the ends of each roller that mesh together so that they roll at the same time and pull the clay through at whatever thickness you set them at.

- At the thickest setting, the rollers are set as far apart as they can go, which means that the internal gears just barely touch at the tips. This causes them to clunk as they go around… jerking the rollers and leaving roller marks on the clay sheet.

- At the thinner settings the rollers mesh together much better and roll much smoother, leaving the clay perfectly smooth.

- The higher number of setting on the machine, the more range in settings there are. Therefore, the wider spread those gears have to go between the thickest and the thinnest settings, and the bigger the ‘clunk’ at the thickest settings.

- However, there are a few things you can do to help minimize those roller marks from happening.

- The lines are the worst when you force a thick piece of clay through the thickest setting.

- So what you can do is roll your piece through at the thickest setting and then roll it through again at the same setting to flatten the marks out a bit.

- Giving your piece a quarter (90 degree) turn in between passes, will also help to remove the lines from the first pass through.

- It also helps if you kind of pull on the sheet as it is being drawn through the rollers. It causes some resistance on the rollers and helps to minimize the “lurch and clunk” factor.

- When you really want a smooth sheet, just roll the sheet at a thinner setting.

- If a smooth but thick sheet is needed, then consider rolling at a thinner setting and doubling up the clay to make a thicker sheet

00:00:03 –> 00:00:07 Hi guys, its Cindy Lietz, your Polymer Clay Tutor, and today’s Studio Tip, I’m gonna be

00:00:07 –> 00:00:14 talking about how to avoid getting roller lines on your Polymer Clay by your pasta machine.

00:00:14 –> 00:00:21 Now, sometimes you’ll grab a chunk of clay… and this happens to be a piece of Sculpey

00:00:21 –> 00:00:26 Soufflé Clay, and it’s the color Pumpkin, which is a pretty color, and you’ll run it

00:00:26 –> 00:00:31 through the pasta machine at your thickest setting and you’ll get these lines on it,

00:00:31 –> 00:00:37 and it doesn’t matter…now hopefully Doug can pick up on those lines, can you see them,

00:00:37 –> 00:00:41 there, ok good, it doesn’t matter if you’ve got a beautiful pasta machine like this new

00:00:41 –> 00:00:49 one I have… an Atlas Machine, or if you have a low end one, often at the thickest

00:00:49 –> 00:00:55 settings you’ll get those lines, and the reason for that is because of the gears.

00:00:55 –> 00:01:01 Now, I had an old pasta machine but I couldn’t find it, I was gonna show it to you how they

00:01:01 –> 00:01:07 work, but the rollers here, we’ve got 2 rollers in the pasta machine that turn when you roll

00:01:07 –> 00:01:12 your clay through, and basically, I have a couple of…these aren’t real gears, these

00:01:12 –> 00:01:17 are just ones you use for jewelry, but it’ll give you the idea, there’s a gear at the end

00:01:17 –> 00:01:25 of each roller and when they’re at the thickest setting, the gears are quite far apart, and

00:01:25 –> 00:01:32 so they just touch on the tips when they’re going through and they kinda clunk together,

00:01:32 –> 00:01:35 and you can hear that, hear it clunking?

00:01:35 –> 00:01:41 Well, when they get down to the smaller settings, the gears come closer together, and they mesh

00:01:41 –> 00:01:45 better together and you can hear that here, so if I have it on the thickest setting it

00:01:45 –> 00:01:50 clunks, and as I go down, it’s get quieter and quieter and quieter, until when I’m in

00:01:50 –> 00:01:55 the middle here, I can barely hear it, and that’s because those gears are meshing together

00:01:55 –> 00:01:56 really beautifully.

00:01:56 –> 00:02:02 And the more number of settings you have…so the wider range of thicknesses, the more those

00:02:02 –> 00:02:07 thicker settings are gonna be just at the very edge of their gears, otherwise at the

00:02:07 –> 00:02:12 thin settings, there’s not gonna be enough room to get all the way to the…you know,

00:02:12 –> 00:02:19 inside here, so when you’ve got a ton of settings…all the way out to 9, so this goes from 1 to 9,

00:02:19 –> 00:02:21 the 1 kinda just clicks away at the very end.

00:02:21 –> 00:02:28 So there are a few little things you can do to help minimize that, first of all, it happens

00:02:28 –> 00:02:34 when you first kinda have a thick sheet, it’s doubled up and you’re pushing it through,

00:02:34 –> 00:02:39 so it clicks away, if you run it through one more time again, and especially if you kinda

00:02:39 –> 00:02:45 hold on to it and let it pull through a bit, that’ll also help minimize those roller lines,

00:02:45 –> 00:02:47 so those are a little less there.

00:02:47 –> 00:02:55 And if I take it and then turn it that direction and roll it again, they pretty much disappear,

00:02:55 –> 00:03:00 now if…that’s only if you really have to have it at that thick setting.

00:03:00 –> 00:03:06 Now at the thick setting on this machine, it comes out to be 8 playing cards thick,

00:03:06 –> 00:03:13 so what you could do instead is roll it down to a thinner setting, so that’s at a 2,

00:03:13 –> 00:03:20 we’ll go down to the number 3 on here is 4 cards…playing cards thick, and it’s very

00:03:20 –> 00:03:24 smooth, I can’t see any lines at all, and then I can just double it up if I wanted the

00:03:24 –> 00:03:25 8.

00:03:25 –> 00:03:30 Or like I said, you could just kinda pull on it when it’s at the thicker setting, so

00:03:30 –> 00:03:34 I’ll just show that to you again, when it’s at the really thick setting if you kinda hold

00:03:34 –> 00:03:40 on to it and let it pull through, it’ll be less lines and then if you turn it sideways,

00:03:40 –> 00:03:46 you can kinda erase them, or you can just roll it at a thinner setting to help avoid

00:03:46 –> 00:03:47 that.

00:03:47 –> 00:03:52 Alright, so I hope you understand why that is happening and how you can avoid it.

00:03:52 –> 00:03:59 And I hope you like this video, if you do…do, if you did, do let us know.

00:03:59 –> 00:04:05 And if you have a question in regards to Polymer Clay or working with it or products you can

00:04:05 –> 00:04:12 use with it, chances are that we’ve already done a video on it, and if we haven’t we can

00:04:12 –> 00:04:17 make a new one for you, so why don’t leave your suggestions in the suggestion…or in

00:04:17 –> 00:04:22 the comment section below and we can put it on the list.

00:04:22 –> 00:04:25 Alright, so we’ll see you next time and bye for now.

Our goal is to translate these videos into as many languages as possible. If you are interested in helping with this initiative, then please do contact us and we will figure out a way to make it worth your while :)

Resource Links:

- Related Video: My Brand New Atlas 150 Pasta Machine

- Related Video: Polymer Clay Pasta Machine Cleaning

- Related Video: Using Translucent Clay To Clean Your Pasta Machine

- Related Video: Why Some Pasta Machines Leave Black Streaks

Resources marked with a double ** asterisk are affiliate links. If you click on them and decide to buy something, we may receive some compensation. This does not affect the price you pay in any way. What it does do, however, is helps us to continue providing free videos for you, here at the PcT website. Using our links to purchase your tools and supplies, is always greatly appreciated.

Sponsored Ads & Special Promotions

Shareable Images

To share this full blog post anywhere on the web that allows links in comments, here's a shortened url to copy and paste...

>> https://mypct.ca/v641 <<

Want to chat about today’s post? That’s what the comment section below is for. Scroll Down… We’d love to hear from you!

Or... if you would like to request a topic for a future post, here is the link to do that… PcT Suggestion Box

Hi Charmaine, at the top of this page you will find a Basic Course tab that you can click on and it will allow you to purchase her inexpensive basic/beginning course that is highley recommended for anyone just starting in clay. It has everything you need to know and is well worth the cost. As far as using your pasta machine, that is also covered in detail. It is best to slice your blocks in sections, roll them out a little with your hand roller and then run them through the pasta machine on your thickest setting whichever your machine has. Most have a NO. 1 through 7-9. Good luck and welcome to Clay Heaven!

Hi Cindy,I’m extremely new to this and super excited to get started. I just purchased the pasta this past Friday 6-27-16. Ready to jump in and give it a shot however do I slice 1/4 of the clay roll it in a ball and then insert it in the machine or do I adjust the dial to 4 and then insert the 1/4 block of clay and then crank for the smoothness. I’m so lost but eager

I am in a quandary re: both pasta machine and extruders. I have watched most of your videos re: this subject. I started out w my original Atlas “thrift store” purchase (new). I have been using it for a year but it does leave the black streaks. I switched to Makins machine with wider rollers and supposed patented to not leave streaks. However, after using it with very stiff clay it has become weakened.

I then ordered the Atlas 150 that you got in gold, (I got the copper) and the motor. I have not used it yet as I noticed that the rollers were narrow v. the Makin rollers.

What is your opinion as the Atlas was expensive but I will keep it if it is worth it. And the motor?

Do you use it?

Do you think the wider rollers ( Makin) are better for Skinner blends?

Your help would be greatly appreciated

Thank you, Marilyn

Hi Marilyn, I love my Atlas 150. It has been a great machine for me. I don’t have a motor for it. The anodized aluminum rollers have stayed streak free and the over all machine has remained sturdy and trouble free.

As far as the rollers being wide enough… I have never had an issue with the size of this machine… but I have never worked with a wider one, so I wouldn’t know the difference. With the blending part of Skinner Blends, skinnier is easier any way, but if you wanted to make really wide sheets for decor pieces or something, wider may be better. Atlas does make a 180 which is wider, but I don’t know if they make them with the anodized aluminum rollers or not. But you could look into that.

There is a new machine coming out by Lucy Clay Tools that may end up being the best machine for polymer clay on the market, but it is still in production and I haven’t had the opportunity to test it to know for sure… but the specs look very promising. It iwill be larger, have a better gear system, greater range in thicknesses, streak free rollers (I think) and can have a motor. I do believe it will probably end up being more expensive than the Atlas, so there’s that to consider as well.

Any, until that new machine comes out, my Gold Atlas 150 is currently my favorite machine I have ever had. It is definitely worth the $100 I paid for it.

I’m new to this art/craft and your videos are amazingly helpful!!

I am getting deep ridges in my clay. It seems to get worse as the clay gets conditioned or warmed. The ridges get worse as the settings get thinner as well, it’s driving me nuts and I’m not able to use the clay then. Any idea or suggestion?

You are the only one I could find that addresses this and two extremely experienced artists didn’t know and referred me to this video!!

Thank you!!

Stacy other than the advice I gave in this video, there is not much you can do… except get a new machine. I suppose if you tried leaching the clay a bit (do a search on leaching clay in the search box at the top of the page) it may help. Stiffer clay usually doesn’t wrinkle as bad. You can also try rolling it with an acrylic roller, after, but that kind of defeats the purpose of having a pasta machine. Once the gears start slipping… there isn’t too much you can do. Good luck!

Hi Cindy,

I’m experiencing the same problems as Stacy – but I’m working with a brand new Atlas 150. It arrived yesterday and as soon as it was set up and I put the first sheet through, there were ridges. The thinner the setting, the more rippled and warped the clay became. I thought that perhaps the gears were misaligned so I took off the side panel to take a look but they seemed to be just fine.

Since stepping away from the machine last night, I’ve been Googling pretty frantically to figure out what the problem might be. I realize that as far as returning the machine, I’m probably out of luck because I’ve already used it for something it’s not meant for. I’m wondering if my rollers aren’t lined up straight, which could cause the clay to sort of squish out at the higher settings instead of rolling out smoothly.

I realize that no one has all the answers, but when it comes to these sorts of things, you’re probably my best bet! Do you think it would be worth it to have it checked out by someone who maintains/fixes small appliances? I’m honestly so frustrated I could cry, I was so excited to receive my pasta machine so I could start making skinner blends and all sorts of things, and it’s leaving me with a textured, shredded mess LOL

I appreciate any advice you can give me.

Hi Sarah, sorry to hear you are having such issues. I personally have not had any issues with this particular machine, but I am hearing more and more people are having problems. It is either that they are skimping on quality or that they are reselling broken machines without checking them, but it is an issue with the machine, not you.

You need to contact the company and tell them exactly what you told us. If the machine is not working properly, they NEED to deal with it. These companies are making a ton of money from the polymer clay niche and they need to acknowledge that. If it is brand new, and it isn’t rolling properly, then they need to replace it.

Don’t go to an appliance person. That will just cost you money and they may not be able to help.

Let us know what they say.

Hi Cindy,

Thought I’d update you!

I’ve mainly been using my machine on the thickest 2 or 3 settings, simply to produce sheets that have a uniform thickness, and that alone is hugely helpful after only using an acrylic roller for so long. I’ve also been using it to condition so of my more crumbly/stiff clays (including Super Sculpey firm) and my hands are practically singing with relief!

One thing I noticed as I put the stiffer clays through the machine was that the rippling wasn’t half as bad as it was with the softer clays. After a bit of fiddling, I’ve found that my best results come from leaching softer clays quite a bit and making sure they don’t get too warm when I’m working with them. Even then it’s still sort of a gamble as to whether or not I’ll get ripples in my clay as I work my way up into the thinner settings, but right now I’m much less flustered than I was when I first got my machine. I’ve actually been able to do some pretty fun stuff without a ton of trouble – Claire Wallis’ water cane, in particular!

Thanks for replying so quickly when I was so bummed out, and thanks for giving me the confidence to contact Atlas. Even though I’m feeling a little better about my machine, I do think I’ll send an email their way.

Hope you’re well, keep up all your great work!

Good to hear the update Sarah! I am glad that you have figured out a way to make it work for you. Thanks for coming back and letting us know!

Maybe roller lines could just be my signature style. LOL.

Hi Cindy!

Your timing is perfect! Just a day or two ago my husband Geoff walked into my clay room as I pulled a piece of clay from my pasta machine. He asked why the sheet had funny lines on it. I didn’t have an answer, but I wanted one because I’d started noticing it too. I so often feel as if you are holding my hand as I try to put into effect what You teach me..Thank you.

Cindy, bless you, it worked on 3 machines. Now to get the other ones out of the cupboard, lol. One for white, one for red, one for translucent……hee hee.

I’ve never had problems with these lines but I do appreciate the video so I can pass the information on to those who do!

Hi Cindy!

First of all – horrors – you’re not wearing polymer jewelry! At least, it sure looks like you only have wire earrings on.

Secondly, I don’t remember where I learned this, but I was told not to use the #1 (thickest) setting on my machine because of the gears being so far apart. (which can easily break the machine if a large chunk of clay is forced in). Apparently the second thickest setting is essentially the same as the first and is a much better choice for rolling out clay.

Maria

Hi Maria, don’t be too horrified, my bracelet was actually made with polymer clay beads from my Arizona Beads Tutorial. I was wearing wire earring I made though. Yeah some people don’t use the #1 setting, but I am real careful not to jam hard clay in that is too thick to start… but if you find there is less clunking if you start at setting #2 than that is perfectly fine.

Two things.

A) Playing card thickness varies by product and one may be thicker than another also between batches/lot number can have a great degree of difference.

B) I have to disagree with the gears being the cause of rippling as the scraper blades itself is more to blame but there can be multiple points that cause this to happen.

I do like your video’s and keep up the good work!

Ed

Hi Ed, if you use regulation playing cards like the ones used for gambling the difference between thicknesses would be so slight that their would be very little difference in the thickness of the clay.

And,as far as the roller marks, scrapers can sometimes be an issue in leaving lines on clay but usually they will leave scratch marks or weird ripples… not these straight line ridges. If the scrapers were part of the problem in this case then it would be a problem for all the settings… not just the thickest ones.