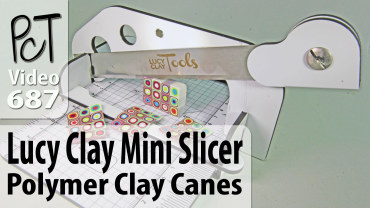

Introducing The New Lucy Clay Mini Slicer

Video #687: This smaller cousin of the original LC Slicer, is a great choice if you don’t need all the features of the larger unit.

More...

IN THIS POST: — lucy clay mini slicer — lc mini slicer — cane slicing — canes — cane — millefiori — mokume gane — canework — slabs — tools — review — demo — czech republic — jiri strunc — (Topics marked with an asterisk* are discussed in the Comments Section below).

Today I will be demoing the brand new LC Mini Slicer by Lucy Clay Tools, a company based out of the Czech Republic. This European styled slicer, is designed to evenly cut small to medium-sized, unbaked polymer clay canes. It’s much smaller than the regular LC Slicer, and is less than half the price. So it is well suited for those who work with smaller canes… have less storage space… want more portability… or simply just can’t afford the larger model. This tool is sturdy and well-designed, though not quite as precise or as versatile as the larger unit. The LC Mini Slicer is currently only available direct from the manufacturer (see link below video), but will be eventually be made available through the other regional distributors at some point. It is good quality and a very useful product to have in your studio.

00:00:03 –> 00:00:08 Hi guys, its Cindy Lietz, your Polymer Clay Tutor, and today’s PcT Product Demo, you are

00:00:08 –> 00:00:14 going to see the new LC Mini Slicer from Lucy Clay Tools.

00:00:14 –> 00:00:18 Now this is a brand new product that they’ve just launched, it’s not even at all of the

00:00:18 –> 00:00:24 distributors yet, but we were lucky enough to have one sent to us and I’m gonna show

00:00:24 –> 00:00:25 you all about it.

00:00:25 –> 00:00:32 Now, we have talked about the Lucy Clay regular slicer before…and here’s the Momma here,

00:00:32 –> 00:00:39 she’s a lot bigger than the Mini Slicer and there are some differences, a few of which

00:00:39 –> 00:00:41 I’m gonna show you.

00:00:41 –> 00:00:47 One of the big differences is the price point of course, now this…with the current prices

00:00:47 –> 00:00:54 today, at time of filming, this Mini Slicer is $99 dollars…

00:00:54 –> 00:01:02 US ones, and the large regular one is $215 US dollars, so there’s quite a difference

00:01:02 –> 00:01:07 there, and they have different benefits and different advantages.

00:01:07 –> 00:01:14 So first of all, the Mini Slicer, it’s for slicing Polymer Clay canes, and the whole

00:01:14 –> 00:01:20 reason why we have all these slicer products coming out now is because people do have a

00:01:20 –> 00:01:30 bit of a tricky time trying to slice really even perfectly straight slices by hand, now

00:01:30 –> 00:01:34 once… if you practice, and practice, and practice you can do it by hand, and you don’t

00:01:34 –> 00:01:40 need a slicer, but these things just really help keep it straight, keep it even and that’s

00:01:40 –> 00:01:42 why everybody loves them so much.

00:01:42 –> 00:01:47 So I’ve got a couple slices here that I did of the Mod Cane that we did a little while

00:01:47 –> 00:01:54 ago in a video, and I’ve got a couple slices here that I did with the Lucy Clay Mini Slicer,

00:01:54 –> 00:02:01 this one here is 1/8th inch thick, and this one is 1 millimeter thick, and you can see,

00:02:01 –> 00:02:07 it’s perfectly even and straight and beautifully cut.

00:02:07 –> 00:02:16 Okay, so let me just show you a little bit about this machine, it is…okay so the Lucy

00:02:16 –> 00:02:22 Clay stuff is really nice, it’s really got… it’s beautifully designed, it has that European

00:02:22 –> 00:02:30 look to it because they are made in the Czech Republic, and they have that…they come in

00:02:30 –> 00:02:37 a box that is…you usually have to assemble most of their products, and they’re fairly

00:02:37 –> 00:02:38 easy to do.

00:02:38 –> 00:02:48 This one is made of a product called Die Bond, which is a little bit similar to… the only

00:02:48 –> 00:02:52 way I can really describe it is it’s sorta like card board only it’s not cardboard, so

00:02:52 –> 00:03:00 the pieces are all cut out of this material…like I said it’s called Die Bond, the center Black

00:03:00 –> 00:03:07 part here is like a high density plastic, and then the outside layers are steel…painted

00:03:07 –> 00:03:15 steel, so they’re really strong and durable, they have a really nice clean look to them,

00:03:15 –> 00:03:20 and all the pieces are kinda like this, they’re like parts, and they would come flat in the

00:03:20 –> 00:03:22 box.

00:03:22 –> 00:03:28 There’s a sliding base… you would probably have to put the sticker on, mine already had

00:03:28 –> 00:03:32 its sticker on, but most of them will come with…you’ll need to put your sticker on

00:03:32 –> 00:03:33 your sliding base.

00:03:33 –> 00:03:38 They all have this plastic film on it that needs to be peeled off, it’s a protective

00:03:38 –> 00:03:45 film, and the parts here would have to be assembled.

00:03:45 –> 00:03:53 Now this piece here would have been completely flat and then you just would fold up the edges,

00:03:53 –> 00:03:59 the piece on the end here for the handle was more like a little butterfly wing, so those

00:03:59 –> 00:04:05 sides would have been folded up, and then you bolt it on to the blade, you snap all

00:04:05 –> 00:04:06 the pieces together.

00:04:06 –> 00:04:12 And the instructions are quite simple, they have them all here, they have them in the

00:04:12 –> 00:04:19 print out that they give you with the tool…the camera may or may not pick up the details

00:04:19 –> 00:04:24 very well, because some of the printing is quite light, but the instructions are here

00:04:24 –> 00:04:27 on how to fold your pieces and assemble it all together.

00:04:27 –> 00:04:35 You can also go online at lucyclaytools.com and they have some videos and that kind of

00:04:35 –> 00:04:41 thing to assemble these pieces, they have the videos also up on YouTube, so… if you

00:04:41 –> 00:04:42 need help with that.

00:04:42 –> 00:04:48 Now, the simple is nice and clean…its, or the simple…the design is quite simple and

00:04:48 –> 00:04:51 nice and clean, easy to use.

00:04:51 –> 00:05:00 Now the advantages to this machine are that it’s small, it’s a lot less expensive, so

00:05:00 –> 00:05:06 it’s not using up a lot of your work space, but the disadvantage is also that it’s small,

00:05:06 –> 00:05:15 so it can do lots of the smaller canes…any of the smaller canes, but a larger cane like

00:05:15 –> 00:05:22 even this Winter Sweater Cane that we did back at Christmas time, this is just even

00:05:22 –> 00:05:28 too big to fit through, it’s just too long and too wide, it’s just about the right size

00:05:28 –> 00:05:34 but not quite, so you’re not gonna be able to do really large canes or large slabs on

00:05:34 –> 00:05:37 this Mini Slicer.

00:05:37 –> 00:05:43 Nor are…well another thing is a really long cane is obviously not gonna fit within this

00:05:43 –> 00:05:48 window here…Doug and I were talking, and we realized that if you really had a long

00:05:48 –> 00:05:55 cane, what you could do is you could slide this piece off here, and then cut your cane,

00:05:55 –> 00:05:59 but you’d have to cut it backwards, normally you would go the other direction, but you’d

00:05:59 –> 00:06:06 have to slice it backwards and go that way, I would put it…always put it right back

00:06:06 –> 00:06:10 on though, because this is the piece that would keep everything nice and square, so

00:06:10 –> 00:06:16 you’re gonna wanna make sure to keep that on there unless you need it for a longer cane.

00:06:16 –> 00:06:22 Alright, so it’s quite neat, I’m gonna put a piece…I’m gonna put a cane in here…now

00:06:22 –> 00:06:30 the other thing is that it is all manual, the regular slicer has a little dial on the

00:06:30 –> 00:06:39 back that helps ease your cane forward and backwards, so it can be very, very precise,

00:06:39 –> 00:06:47 and also the larger unit has this back plate here that supports the back of your cane,

00:06:47 –> 00:06:53 the Mini Slicer doesn’t have the back support thing, it just sits on the tray.

00:06:53 –> 00:06:58 You also have to kinda line it up and figure out where it’s starting and then bring your

00:06:58 –> 00:07:04 blade down, now, it has a little magnet here that will hold your blade up so that you can

00:07:04 –> 00:07:08 work underneath it without it falling down which is a nice safety feature, and it also

00:07:08 –> 00:07:18 helps to pull that blade up against this back support piece, because you can kinda pull…there’s

00:07:18 –> 00:07:23 wiggle there, I’m not sure if I’m at the right angle for you, but you can see that there’s

00:07:23 –> 00:07:24 wiggle here.

00:07:24 –> 00:07:29 So it’s really important when you bring your blade down that you keep the blade up against

00:07:29 –> 00:07:36 this base here, otherwise, you’re going to have it not cut straight, and also, it wouldn’t

00:07:36 –> 00:07:40 fit down into this slot at the bottom and it wouldn’t come all the way down, if you

00:07:40 –> 00:07:46 had it pulled away from the base here, okay, so that’s important, you’re just gonna wanna

00:07:46 –> 00:07:49 keep it up against there when you go to cut.

00:07:49 –> 00:07:54 So then what I’m gonna do is I’m gonna just sort of… the first piece is always a little

00:07:54 –> 00:07:59 off, ‘cause I gotta figure out where the front is, gonna slide it ahead a little bit,

00:07:59 –> 00:08:06 and then take my first piece, come right down, and it’s always gonna be a little bit off

00:08:06 –> 00:08:15 because you haven’t got… it’s your first cut, but then… now the one way you can keep

00:08:15 –> 00:08:22 these things really accurate is by watching where the markings are on the base.

00:08:22 –> 00:08:30 And I’m gonna use this front part here as my guide, and if this is my first slice now,

00:08:30 –> 00:08:38 I can just mark, take a non-permanent pen…so something that’s water based, this is a Lumicolor,

00:08:38 –> 00:08:45 non-permanent pen, and I’m just gonna mark where my first area is…where I’m starting,

00:08:45 –> 00:08:55 and if I’m gonna do millimeters, I could use this little guide here, this one here is the

00:08:55 –> 00:08:59 Imperial so that one’s gonna be like eighths of an inch.

00:08:59 –> 00:09:05 But what we can do now… when I slide this up, I can move this forward, and I can just

00:09:05 –> 00:09:11 use whatever guide, so if I’m gonna move it…use the 1/8th of an inch, I’m gonna just make

00:09:11 –> 00:09:18 sure that the next slice is moved up an 1/8th of an inch, and then when I cut down, it’s

00:09:18 –> 00:09:24 going to be exactly an 1/8th of an inch thick, and same goes for the millimeter if I wanna

00:09:24 –> 00:09:29 just use the millimeter guide, I could see that, and then because we used the non-permanent

00:09:29 –> 00:09:34 pen, what we can do is just wipe that off with like a baby wipe or a damp cloth or something

00:09:34 –> 00:09:35 like that.

00:09:35 –> 00:09:39 So that’s what I found as a good little trick for making sure that you have exactly the

00:09:39 –> 00:09:41 right… same thickness every single time.

00:09:41 –> 00:09:48 Alright, so you can see it’s quite easy to use, the blade is super sharp so be careful,

00:09:48 –> 00:09:52 it’s simple and it’s a great little product.

00:09:52 –> 00:09:57 Now of the two, if you’re trying to decide which do you want, you’re gonna decide on

00:09:57 –> 00:10:03 what your use is, so if you are a commercial artist, someone like me who does a lot of

00:10:03 –> 00:10:11 larger canes, a lot of…everything more on a larger scale then you’ll want to have the

00:10:11 –> 00:10:13 larger slicer.

00:10:13 –> 00:10:20 If you do just mostly small canes and small slabs, you don’t have a lot of storage space

00:10:20 –> 00:10:26 or your budget is a little smaller, then you may be interested in the LC Mini Slicer.

00:10:26 –> 00:10:34 Alright, so like I said, they are available… right now they’re only available on lucyclaytools.com,

00:10:34 –> 00:10:39 and they are gonna start going out to the other distributors later, they said soon,

00:10:39 –> 00:10:41 ‘cause it’s just brand new launched.

00:10:41 –> 00:10:45 It’s a beautiful product, I really like it it’s nicely made.

00:10:45 –> 00:10:49 So I hope you enjoyed that and that it was helpful for you.

00:10:49 –> 00:10:56 And if you have some products you’d like me to demo, if you’ve got techniques you’d like

00:10:56 –> 00:11:02 to learn more about, if there’s something that you just don’t understand, there is a

00:11:02 –> 00:11:06 pretty good chance we’ve already done a video on it, ‘cause we’ve done a ton, so make

00:11:06 –> 00:11:11 sure to go through our channel and through our blog and see what we have already made,

00:11:11 –> 00:11:13 and see if we can help you there.

00:11:13 –> 00:11:19 If not, you can leave a suggestion in the comment section below, and maybe we can make

00:11:19 –> 00:11:22 a video for you in the future, alright?

00:11:22 –> 00:11:24 So we’ll see you next time and bye for now.

Our goal is to translate these videos into as many languages as possible. If you are interested in helping with this initiative, then please do contact us and we will figure out a way to make it worth your while :)

Resource Links:

- Lucy Clay Tools: Lucy Clay Tools LC Mini Slicer

- Related Video: Lucy Clay Brand Polymer Cane Slicer Demo And Review

- Related Video: Polyslicer Combo Tool For Slicing Polymer Clay Canes

- Related Video: Simple Slicer Tool for Cutting Polymer Cane Slices

- Amazon: Lucy Clay Tools LC Mini Slicer **

Resources marked with a double ** asterisk are affiliate links. If you click on them and decide to buy something, we may receive some compensation. This does not affect the price you pay in any way. What it does do, however, is helps us to continue providing free videos for you, here at the PcT website. Using our links to purchase your tools and supplies, is always greatly appreciated.

Sponsored Ads & Special Promotions

Shareable Images

To share this full blog post anywhere on the web that allows links in comments, here's a shortened url to copy and paste...

>> https://mypct.ca/v687 <<

Want to chat about today’s post? That’s what the comment section below is for. Scroll Down… We’d love to hear from you!

Or... if you would like to request a topic for a future post, here is the link to do that… PcT Suggestion Box

I have the larger regular slicer and love it for millefiori style canes. I recently bought the mini slicer for techniques like Natasha beads where I don’t want to pull out the larger slicer. I’m experiencing the same pull back issue. I ended up getting a diagonal cut! There’s definitely a learning curve. I love my larger Lucy slicer, with the turning knob and rigid blade, there’s very little margin for error. I’ve been making more canes since I bought it! The price is a little steep, but I think it’s worth it. I don’t waste my precious cane pattern with imperfect slices, and I get so much more out of it because I can cut paper thin slices.

I bought the LC slicer and I love it. It is bigger than the mini but the footprint is not that large. I wasn’t sure if I was purchasing something that I would only use once in a while but I have found that it is now a go-to-tool. I found a permanent spot on my clay table for it.

So why do I love it so much? I don’t have to think or be careful about my slices any more. Once you set up the cane so that the slicer will take a paper-thin clean cut you are ready to slice to your heart content. I have marked my dial with 1/4 turn increments and then decide how many marks I want to spin it and take the slice. It is repeatable and doesn’t take much time to cut all the pieces you want from a single cane. Some times when I want a couple of different canes cut to the same thickness I will set up all the canes at the same time and then in no time I have them sliced.

I like that the blade comes straight down on my canes instead of at a diagonal like the mini is set up. I also found that I had to go back and purchase the LC Angle base so that the gap is filled in and you can take slices to the very end of your cane.

Cindy asked me to come and post my feeling about the purchase and I must say it is expensive but I can’t see me not having one ever in the future.

I’m glad that you like the slicer so much. Having the angle base really helps. I make a lot of canes and I don’t think I would ever want to go back to slicing them by hand.

Just want to give a shout out to Diane Bruce for the care and attention she gives to customers who purchase the Lucy Clay Tools through her online store.

There was another PcT member here, who purchased through someone else, and then ran into some problems with the order. It was Diane that ended up making everything right. So… my suggestion is to definitely look her up if you are in the market for Lucy Clay Tools :-)

Thank you Doug.

Anna, I’m curious about how you are handeling the Mini Slicer. Are you still having issues with it? I’m still not sure if I “need” one just yet. I like the concept but, I wonder how easy it really is to use. I talked to Cindy about this and she does recommend the larger one if you are to invest in one. But, I don’t work with huge canes that much. Or projects that require many uniform slices. I know getting new tools is super cool! Hopefully, you are finding it helpful.

I am getting the hang of it more but I still am not sure why it pulls back. The best feature of the slicer is the extreme sharp heavy duty blade providers consistent pressure across the blade while slicing.

I have a friend that has purchased several cane slicers and this does work the best.

It is not very often that I need exact slices but I am covering wine glasses with the exuded retro cane and it is much easier if the slices are the same thickness. I have covered many wine glasses with PC and recommend placing the clay on the glass in slices even if you are not using a patterned cane; covering a curved object is tricky.

I would love to have the large LC slicer but cannot justify the $250.00. It is a great tool for many people but just don’t do that much with clay.

I hope to post my wine glasses on Cindy’s Facebook soon.

Anna

Anna, because the slicing plate is movable, I find it a lot easier to hold the plate in place when I am slicing with the mini slicer. I use my left hand to move the slicer plate for the next slice and then I keep the plate in place by bracing my thumb and middle finger against the small end piece. (the piece that Cindy took off in the video). I hold the slicer plate down with the palm of my hand so that it doesn’t move when I slice.

It takes some practice to be able to slice evenly. I practice with a log of junk clay, just slicing over and over again. Slicing a cool cane is actually easier than slicing a warm cane, so I don’t think that is an issue. Please feel free to email me with any more questions you have and if you need a new grid decal I have some.

Thanks for the tips. I was using a similar technique and kept reminding myself to watch where all my fingers were before pushing down. The slicing plate does not move back very much but I kept wondering if I was doing something wrong.

i bought the LC mini slicer and have been having some problems with it and I am looking for suggestions. It seems to pull the “moving plate” backwards when beginning to slice through the cane. I am not sure if it is because the cane is cool after rested at room temperature of about 70 degrees. Mine did not come with the grid decale on the slicer plate, it was hard getting it on straight.

I just wanted everyone to know that I do have the minislicer being delivered to me today. I will have the listing for it up on my Etsy shop later on in the day.

Thank you Cindy for the demo on the LucyClay Mini Slicer. It is really a neat tool to have especially if you want to take it on the road with you and don’t have a lot of room to pack the big one. I can see several reasons why it would be nice to have one just because it is smaller and more compact. I was kind of on the edge as to whether I wanted to order one or not but after seeing your demo, I think I am going to go for it. This would also make a wonderful gift considering the lower cost.