Pasta Machine Cleaning Tip 2 Scraper Build-Up

Video #436: How to keep the inside of your polymer clay pasta machine spic and span.

More...

IN THIS POST: — pasta machine — conditioning machine — sculpey — amaco — cleaning — scrapers — (Topics marked with an asterisk* are discussed in the Comments Section below).

Topics Covered In This Video:

- In Cleaning Your Pasta Machine Tip #1, I showed you how to use a disposable kitchen or baby wipes to clean your pasta machine from the outside.

- But even with a thorough outside cleaning, you’ll still run into situations where you roll a fresh clean sheet of polymer clay through your pasta machine that ends up looking all streaked or dotted with colors from previous projects you’ve been working on.

- What’s happening is that you’re suffering from Scraper Build-Up.

- Now, the way a polymer clay pasta machine works is that each roller has a matching scraper assembly. The scraper is supposed to lift or peel the clay off the roller as it comes ’round, and therefore keep the rollers clean.

- But what can happen over time, is that the scrapers get bent or dinged… which causes gaps for clay to sneak by the scrapers. Using sticky clay accentuates the problem. Trying to jam hard clay through your machine also makes matters worse. All of these things lead to the dreaded Scraper Build-Up problem.

- So today, what I’ll do is show you some tips on how to clean your pasta machine from the inside.

- I’ve got the Sculpey Clay Conditioning machine, but most machines are set up in a similar manner.

- We used to be able to take these kinds of machines apart and do a very thorough cleaning. It was a pain, but it was do-able. However, the new pasta machines are designed so that you can’t dismantle them. Well you can… but you probably won’t be able to get them back together again. So I would suggest you forget about trying. We’ll just have to do our best to clean from the outside.

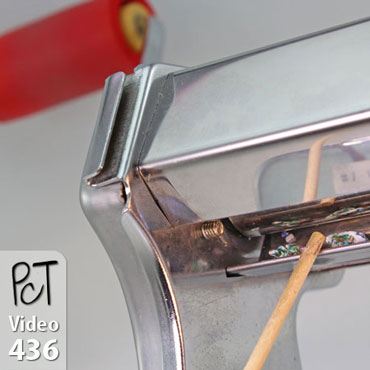

- What you will need is a bamboo skewer or soft flexible plastic knife (no metal utensils), and do your best to remove the built up of clay behind the scrapers, like I show in the video. The back scraper on my machine has a smaller fin, so it is easier to clean on that side. With a little patience, you should be able to remove the bulk of the built up clay and clean your machine relatively well.

- If you clean your machine on a regular basis, your machine will last a lot longer and your clay will come out looking a lot cleaner.

00:00:03 –> 00:00:07 Hi guys, its Cindy Lietz, your Polymer Clay Tutor, and today’s Studio Tip is cleaning

00:00:07 –> 00:00:14 your Polymer Clay pasta machine tip number 2, and this time, we’re dealing with scraper

00:00:14 –> 00:00:15 build up.

00:00:15 –> 00:00:20 Now, in tip number one of cleaning your pasta machine, I showed you how to use a baby wipe

00:00:20 –> 00:00:24 or some sort of cleaning cloth to clean your pasta machine on the outside.

00:00:24 –> 00:00:29 Well, sometimes, you’ll roll a sheet of new clay through, your machine all looks clean,

00:00:29 –> 00:00:35 but you’ll still be getting residual bits of clay from other projects onto your nice

00:00:35 –> 00:00:41 clean sheet, so what’s happening there, is you’re suffering from scraper build up.

00:00:41 –> 00:00:50 Now, the way a pasta machine works is that it has a roller and it has a scraper, now

00:00:50 –> 00:00:55 the scraper sits up next to the roller and when you’ve got your clay coming through

00:00:55 –> 00:01:01 the rollers at the top here, the clay comes through, and the scraper scrapes off the clay

00:01:01 –> 00:01:03 and it comes through the bottom of your machine.

00:01:03 –> 00:01:07 If you don’t have a scraper, what happens is the clay just collects on your roller,

00:01:07 –> 00:01:12 it would go around and around and all get bunged up on there.

00:01:12 –> 00:01:18 Obviously we need a scraper, but what can happen is, over time, as your scraper gets

00:01:18 –> 00:01:23 bent, or if there’s any sort of little gaps or anything between your scraper and your

00:01:23 –> 00:01:27 roller, or if you’ve been putting a lot of sticky clay through, or jamming hard clay

00:01:27 –> 00:01:35 through, clay can sneak down behind that scraper and get built up behind your roller and cause

00:01:35 –> 00:01:40 scraper build up, and that will cause you issues and end up on your nice clean sheets

00:01:40 –> 00:01:41 of clay.

00:01:41 –> 00:01:43 So, what I’m gonna do is…

00:01:43 –> 00:01:51 I’ll just show you how to clean your machine, now I’ve got this Sculpey Clay Conditioning

00:01:51 –> 00:01:55 machine, most of the machines are pretty similar in their design, you’ve got the rollers

00:01:55 –> 00:02:00 at the top, you’ve got the scrapers underneath and then you have these sort of fins on the

00:02:00 –> 00:02:05 outside that just sorta hold the whole thing together and kind of protect the rollers.

00:02:05 –> 00:02:10 Well, we used to be able to take these machines apart, the way the design was, it was a pain

00:02:10 –> 00:02:14 but it was doable, now… the way their designed, they have some pins inside and everything

00:02:14 –> 00:02:18 else, if you take it apart, the whole machine falls apart and you can’t get it back together,

00:02:18 –> 00:02:23 so you’re lost if you try to take it apart, so just forget about trying to do that, and

00:02:23 –> 00:02:26 we can clean it the best we can from the outside.

00:02:26 –> 00:02:34 Now, inside…the front side has a logo on it, right here, but on the back side, it’s

00:02:34 –> 00:02:39 a little easier so I’ll show you this first, this fin is a little smaller and you can see

00:02:39 –> 00:02:43 inside here a little better…can you see in there Doug?

00:02:43 –> 00:02:49 And what you can see is, you’ve got your fin here, your scraper here and your rollers

00:02:49 –> 00:02:56 are back inside there, if you can see it, there is some clay building up inside here,

00:02:56 –> 00:03:03 and what you need to do is take something like a bamboo skewer or a soft plastic flexible

00:03:03 –> 00:03:08 knife, and get in there and start gettin’ that clay outta there.

00:03:08 –> 00:03:13 Now you don’t wanna use any metal or anything like that, that will scratch your rollers,

00:03:13 –> 00:03:18 oh and you definitely do not wanna bend your scrapers, now, I would fiddle around there

00:03:18 –> 00:03:21 and get that as cleaned out as I possibly could.

00:03:21 –> 00:03:28 Now, the other side…you can see some shaking out now, the other side is a little trickier,

00:03:28 –> 00:03:36 on this side…the front side, this…the fin comes around the front a little bit further,

00:03:36 –> 00:03:42 and all you have is a small gap here to get at, you may be able to see in this corner

00:03:42 –> 00:03:49 here, there is some clay building up in there, and we can pull that out with my little…oop,

00:03:49 –> 00:03:54 fling it out, and I can see from my angle here that there’s some other clay building

00:03:54 –> 00:03:56 up around that corner.

00:03:56 –> 00:04:01 Now this little flexible one works a little bit better in this spot, now, you’ll never

00:04:01 –> 00:04:05 be able to clean this side all that well, you’ll be able to get some bigger chunks

00:04:05 –> 00:04:11 out, but just because of the access point of it, it never cleans up perfectly, but if

00:04:11 –> 00:04:17 you do this on a regular basis, and work at it and get it nice and clean, your machine

00:04:17 –> 00:04:23 will last a lot longer and your clay will come out a lot cleaner.

00:04:23 –> 00:04:28 So I hope that was helpful for you, if it was, make sure to press that like button we

00:04:28 –> 00:04:30 really appreciate it.

00:04:30 –> 00:04:35 And my question for you today is, do you suffer from scraper build up?

00:04:35 –> 00:04:39 And I’d love to hear your stories in the comment section below.

00:04:39 –> 00:04:43 And don’t forget to subscribe to our channel, we have new videos that come out every week

00:04:43 –> 00:04:44 and you’re not gonna wanna miss a thing.

00:04:44 –> 00:04:46 So we’ll see you next time and bye for now.

Our goal is to translate these videos into as many languages as possible. If you are interested in helping with this initiative, then please do contact us and we will figure out a way to make it worth your while :)

Resource Links:

- Related Video: Cleaning Your Pasta Machine Tip #1

- Related Video: Using Translucent Clay To Clean Pasta Machine Tip 3

- Related Video: Keeping Your Pasta Machine Station Organized

- Related Video: Black Streaks from Pasta Machine on Polymer Clay

- Related Video: Unboxing My Brand New Atlas 150 Pasta Machine

- Amazon: Marcato Atlas Pasta Machine **

Resources marked with a double ** asterisk are affiliate links. If you click on them and decide to buy something, we may receive some compensation. This does not affect the price you pay in any way. What it does do, however, is helps us to continue providing free videos for you, here at the PcT website. Using our links to purchase your tools and supplies, is always greatly appreciated.

Sponsored Ads & Special Promotions

Shareable Images

To share this full blog post anywhere on the web that allows links in comments, here's a shortened url to copy and paste...

>> https://mypct.ca/v436 <<

Want to chat about today’s post? That’s what the comment section below is for. Scroll Down… We’d love to hear from you!

Or... if you would like to request a topic for a future post, here is the link to do that… PcT Suggestion Box

I would love to know in advance when there is a Clay show in my area. Is that possible?

Thank you, Joy

Joy. The International Polymer Clay Association lists upcoming clay events, they have a Facebook page and group. You can also check Polymer Clay magazines such as Polymer Cafe or Polymer Arts, events are advertised or listed in the back of the magazines. .

I just got back from Clay Carnival in Vegas and all 7 expereinced instructors advised against taking the fins off the clay/past machine. These serve a purpuose and helps to make sure the rollers stay alleigned. I have 4 pasta machines and have never taken them apart, they have been used 7 years with no problems.; I clean them using Cindy’s directions and also with paper towels. I have found machines made for Pasta are higher quality than the polymer clay machines made by Amaco or Sculpy. I get my high quality Italian Pasta machines at Goodwill , thrift stores and garage sales: Pasta Queen and Atlas brands are both made in Italy. Thank goodness cooking trends come and go.

You make a good point about the fins keeping the rollers aligned Anna. I never found it to be a problem when mine were removed from my old machine but I was really gentle with my machine and never forced hard clay through it like some people do. But I can really see how the machine would twist if there was a lot of pressure put on the rollers, if the fins aren’t there to keep them straight.

How was the Clay Carnival? I would have loved to have been an instructor there. Wish us Canadians could work in the States more easily…

I recently received a Sculpey Clay Conditioning Machine and ran some fairly soft clay through it and it ended up getting stuck under the scrapers. I watched your video on how to clean them but the clay is soft and sticky and is stuck to the scrapers and wont come off. I was wondering if you had any tips?

I was also wondering what purpose the fins served and if removing them would be an option or if that would permanently destroy my machine. It is a newer model and I know I wont be able to put them back on but I don’t really see the point of them being there. Thank you for all the helpful videos and tips I find them very informative and useful.

Hi Rachel, are you saying that the clay is socking to the rollers and wrapping around them, instead of coming out the bottom? If so, take that machine back… the scrapers aren’t working properly. Don’t take apart a newer machine, even just to take the fins off.. They now have pins inside that hold the scrapers on and taking the machines apart will almost guarantee that it will never go back together again. You won’t be able to return a machine that you took apart, either.

Hi Cindy

Does the Makin core extruder adapter fit the Walnut Hollow Extruder. I want to order it but don’t want something that will not fit what I have.. I love the WH extruder and I bought the vise to hold it to the table … Which also works for holding the dremil tool

Imput from my polymer clay family is greatly appreciated

Natalie aka safti

Hi Natalie:

I have the WH extruder and use the Makins clay core extruder adapter with it. You need to use the WH large round (or other shape) die that covers the small holes in the Makins clay core extruder adapter. Place the clay core adapter so it protrudes through the center of the large round die and then place the assembly in the end of the extruder. Then, extrude as usual. Make sure the clay is very warm and pliable – I often add a drop or two of clay softener and mix it very well before extruding.

Michele

Hi Michelle, thanks for answering Nathalie. I didn’t know that! :)

I have a Makins’ extruder and the WH large adapter. Works fine.

Cindy,

When I get scraper build up I find the best way to clean it out is by using some polymer clay softener fluid.

1. Place machine in a shallow plastic dish.

2. Drip clay softener up and down rollers while turning handle slowly.

3. Let sit a few minutes to soften clay.

4. Use baby oil to flush out clay by pouring over rollers while turning handle, recycle oil and repeat until most clay is gone.

5. Using a plastic toothpick scrape out any stubborn clay bits, then repeat step 4.

6. Finally using some Q tips and paper towels wipe everything off.

Thank you,

Leslie Bassett

Thank you for this tip!

Yes, Cindy, ‘Scraper buildup’ is a permanent problem for me. I try to put lighter clay through first if I’m using more than one colour, and that helps. But eventually I do have to take my PM apart and clean it properly. I’ve just about got the hang of this now, although it still needs 3 hands!

I’ve had 2 PMs for some years now, but one of them stands in pieces never to be used again, because it has those ‘pins’ you mentioned, and, just as you said, it was impossible to get it back together again. I’d like to know if there is some way of telling them apart, as they both look identical. Sooner or later I’m going to need a new one as my trusty machine is showing its age, but when I do how can I be sure I’m buying one with the fins and not the one with the pins?

Many thanks – and I love your earrings! Marion

Hi Marion, I have three older machines, none of which have the pins holding in the scrapers, that are causing the trouble with putting the machines back together. So I am afraid I don’t know how to tell them apart from the outside.

NOTE TO EVERYONE: I wonder if anyone else knows how to tell the new pasta machines with the pins in them, apart from the old machines without the pins? Are there any clues? Can you see the pins peeking out behind the scrapers or something? It would be a good question to find the answer to if anyone out there knows and can share it with us.

If you can’t hold them in your hand out of the box then no I don’t think you would be able to tell.

I have 2 pasta machines one new that I bought for clay and one that’s about 10 years old that I actually used to use for making pasta. I pulled the old one out of the kitchen and flipped them both over and you can clearly see the difference on the two

Hi Cindy,

I have an Amaco machine that I bought in 1999. I recently bought a second one for white clay and there is a big difference in the quality of the two machines. Anyway, I thought I kept my main machine pretty clean, but couldn’t believe the build up behind the scraper. Wow! Thanks for the great tip. I can’t begin to tell you how thankful I am for you and this community.

Hi Cindy, I bought a pasta machine from Mona Kissel and the scrapers screw on and off so I can clean it with no problem. I love this thing, can’t live without it. It was a little expensive but cheaper than buying a new pasta machine every 6 months because I couldn’t get the clay out. I did teach myself how to take the pasta machines apart and put them back together and when I do, I don’t put the fenders on, it’s easier to clean that way. Thanks for all your wonderful videos, love them.

Bonnie, would you mind sharing the makes and models that you have found possible to clean and reassemble? Assume one is a type of Atlas, Italian made machine?

Thank you so much. I had so much clay come out I had to take a picture.

Before getting the “Dream Machine” I had 2 other pasta machines. One I was able to take apart, get rid of the fins and reduce the scrapper build up quite nicely. The other pasta machine I took apart and the parts flew all over. I never was able to get it back together so it got trashed. Now even though I have the Dream Machine, I still get scrapper build up and have to clean the scrapper blades periodically depending on how much I use it. So It really doesn’t matter what machine you have, it still needs to be cleaned and the rollers wiped down to prevent the build up and getting bits of clay so they don’t mix with your new clay. I am just fortunate I can take mine completely apart and do a really good cleaning job but it still takes just as much time and energy.

I have an Atlas I got some time ago and took it apart once to clean it and barely got it back together! I will never take it apart again! This video was definitely helpful. Thanks Cindy!

Very good. Not sure if this is helpful suggestion, not everyone would want the extra cost, but I tend to have two pasta makers and I keep one for white and translucent light colours and the other for darker colours. It’s handy to know how to clean them, I did once took one apart to clean it and just like Cindy says it’s now in the bin ‘cos I couldn’t get it back together.

I did that scraping off the clay with a bamboo skewer, and then I fed a folded sheet of paper through and just pulled it back and forth side to side, up and down. The paper trick got it really clean and I had to change it out several times. Plus with the paper you can get around the different areas inside the machine.

Thanks for the great new video, Cindy. My first pasta machine was an inexpensive craft store model which I always found difficult to keep clean. I recently replaced it with a Marcato 180… what a difference! I purchased a motor, too, but I don’t bother using it LOL. This PM is such a joy to use even with the hand crank, easy to keep clean and sheets beautifully. Just another example of getting what you pay for, I guess. But EVERY machine benefits from a conscientious cleaning routine!

I just cleaned my machine again yesterday… I wish I’d known then not to use metal items… hope I didn’t scratch it.

Well… now I now to stick with bamboo and toothpicks!

Thank you soo much!!! VERY helpful!!

Sometimes I run some Super Sculpey through after cleaning to pick up any other loose bits…

For those who want to ask for a great Christmas gift for your polymer clay habit, check out Mona Kissel’s “Monafied” atlas Pasta Machines.

The blades are modified to be removable, so they can easily be cleaned…and replaced. This is an easy way to keep your white clay white!!! I bought the 150 atlas (the 6″ size) and I love it!!!

Another incredible tip from our AWESOME polymer clay tutor!! :0) ~~Thank you Cindy!! Sherry

Tremendously informative and illustrative video. Thank you.

I can’t live without my pasta machine! :)

They aren’t horribly expensive, around $25 at Hobby Lobby/Michaels and you can use their nearly-constant 40% off coupon which would make it around $15 or so.

I splurged, getting Makins Ultimate Clay Machine which has these fantastic non-stick rollers. It is a great machine, but definitely a bit more on the expensive side, around $50 ($30 w/coupon). Probably not the route you want to go if you are just trying one for the first time.