Polymer Clay Finishes – Which One Is Best?

Choosing the right polymer clay finish for your beads can be puzzling:

More...

The other day I received a question from a subscriber (Sandra Taylor) about polymer clay finishes. There’s a lot of confusing information out there regarding finishes for polymer clay beads, and Sandra is not the first to bring up this topic with me. So I figured today would be a good day to talk about it.

Here is Sandra’s question:

There’s one thing that puzzles me. I made some beads and got some of that Sculpey glaze and what I’m learning that the stuff does peel or turn yellow after a while. Eek!

From reading, I gather that I have to use something called Varathane or Future floor polish — not easy to find. I guess one can’t use just any kind of varnish because it will react with the clay. Do you have any suggestions?

To first address your issue with the Sculpey glaze peeling up. This is a common problem and was most likely caused by excess oils from your hands getting on your beads, causing the glaze to not stick properly. You can solve this problem by sanding (highly recommended) and/or cleaning the bead first with rubbing alcohol before coating with the glaze.

For beads that have already peeled, you can bake them for 10 min or so and see if that works. Personally I don’t like the Sculpey glaze because it is too globby and leaves a plasticy look to the beads. Plus, I think it is too expensive for what you get.

As far as other finishes that were not originally designed for use with polymer clay… you do need to be careful. Many of them are not compatible with the clay. Some even can fool you into thinking they work by appearing to dry up nicely, but then becoming sticky 6 months later. Really bad news if you have sold those beads or gifted them. People just aren’t impressed with sticky jewelry!

Sandra… You are right about Varathane and Future Floor Finish being good products to use. They have both been tested over time on polymer clay and in my opinion are much nicer to work with, not to mention way cheaper than the products out there made for polymer clay.

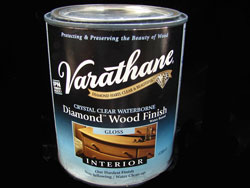

Make sure you get Varathane Diamond Polyurethane Interior (Water Based). Stay away from the oil based Diamond Floor Finish. The Varathane is thick and needs to be put on with a fine brush. It is UV protected and won’t yellow. It dries to quite a hard finish and comes in gloss, semi-gloss and matte. You can find this in the paint section of most home improvement stores. Or get it here on Amazon: Rust-Oleum Varathane Interior Elite Diamond Finish **(Affiliate Link)

For the Future Floor finish you can go to my previous post on Finishing Beads with Future Floor Polish to see what the bottle looks like and get a little tip on using it. Future is very thin and easy to use. I found it in one of the grocery stores local to me (Safeway) without much difficulty.

ADDENDUM: I am no longer recommending Future Floor Finish for polymer clay. It's too hard to find, and there are much better finishes available now.

But to tell you the truth, I am finding the more I work with polymer clay, the less I like to put finishes on my beads. I have found that if I bake the beads for an extended period, they sand and polish up to such a nice shine, that a finish is often unnecessary. Highly buffed beads with no polymer clay finish on them are actually more water-resistant, and you don’t have to worry about globbing that can occur when finishes are poorly applied.

So Sandra and everyone else having problems with your polymer clay finishing techniques, I hope this helped. If you need further assistance, feel free to post your questions below in the comments section.

Sponsored Ads & Special Promotions

Want to chat about today’s post? That’s what the comment section below is for. Scroll Down… We’d love to hear from you!

Or... if you would like to request a topic for a future post, here is the link to do that… PcT Suggestion Box

Hi Cindy

I bought the Varathane that Blue Bottle tree talked about but I also just ordered Dimond Glaze by Judikins … I think I remember someone saying it was a good glaze for polymer clay.. Am I right or was it a mistake to buy it

I don’t know about the Diamond Glaze by Judikins Nathalie, I haven’t used it myself. But the Varathane is good for sure!

Hi Cindy

I appreciate your quick response…. Is there anyone who has used Dismond glaze by Nudikins who can give me some feed back. I do I have one of friend who says she loves it but both of us hav bought the Varathane but as of yet have not used it….I know that different glazes are good for different types of finish depending on what you have added to the clay eg alcohol inks vs person X powders … Any imput would be appreciate… Hope I did not jump the gun I. Ordering the Diamond glaze this morning( $9.00 learning experience…. Hope I can use it for smeth ny when it arrives o. Saturday

Hi Cindy

I make polymer clay fairy garden items…for outdoors.I was using the Diamond varathane(because it was UV repellent) and put the items outdoors after they cured for almost a yr(a fairy garden I had in my dining room).

It rained for a day…all my items turned milky and I noticed the varathane pooled in the crevices of my items.

I then proceeded to do some tests…and I had pcs that were coated in the Diamond varathane..I coated them with minwax indoor polyurethane…let cure and soaked the item in water…still slightly milky.

I tried a pc with Helmsman spar urethane…over the diamond varathane…dried super hard and shiny and did not turn milky after being submersed in water after a day..I read on your blog here that spar urethane is no good and will react with the polymer and go sticky.

My question is do you think the coat of varathane will protect the polymer from spar urethane turning it sticky? How long does it take to tell if it will react with the clay?

Hi Michelle!

Done the same with outside polymer clay items and found that all I needed to do was sand, buff, then apply a quick spray of PYMII.

Preserve Your Memories II is the bomb.

No mold, no milky finish when wet, and I find that it helps prevent the splash up dirt from a good rain. My “ghost pipes” and mushrooms are outside in my Connecticut garden 365/24/7 and seem to be holding up well.

They do not receive direct sunlight.

Also here’s a link to the blog article above, where finishes are discussed (lots of great stuff in the other comments, too).

Hope this helps!

Hi Michelle, I am guessing that the finish that turned white was an indoor finish. An outdoor finish would be OK in the rain. As far as Spar Varathane, I don’t think it was me that talked about that. At least I have no recollection of ever using or recommending it… but I am almost 50, it is possible I forgot! :)

As far as layering different types of finishes, I would use caution… there is a chance there could be an issue with compatibility over time but you can certainly test to be sure. Make sure your test sample sits for several months those, because reactions can take their time to show up. 4 to 6 months is sufficient. Good luck!

You would think it was indoor…but it wasnt…it was an outdoor glaze…even on my wooded items it went milky…might even just be a bad batch of the stuff…who knows?!

It has been outdoors for a week now after I soaked it in water to water test it first and it still looks fine.

I will update if it fails or not…I must say it does look pretty fantastic!

Perhaps it wasn’t stirred very well? That kind of thing can happen if a finish isn’t mixed well. Thanks for giving the update! I look forward to hearing about what happens over time.

Hi Jen!

Any overlap of a finish will show, whether it’s wood, metal, plastic….more so if it’s high gloss. Ideally, the solution is to apply the finish in one layer, but that can be hard to do if the project is large or highly detailed.

The easiest way to remove the overlap ring might be to use high grit wet sanding and a good buff polish as a final step, just as is done in fine car restoration work.

The Dremel or JoolTool would make this process faster and easier than by hand if you are bulk producing.

Polymer clay, if baked thoroughly, can be sanded and buffed to an amazing gloss finish without any application of finish as well.

I’d use the search facility here and query the terms I’ve mentioned as Cindy has done many tutes on sanding and finishing over the years.

Also, the search pulls up many valuable blog comments from members here who have shared a variety of methods to make this process easy.

Hope this helps and all best.

I’m sorry, my actual question seems to have become lost: How does one hold a spherical bead to apply finish to the entire thing in one coat (and subsequently to let it dry)? Every way I’ve figured out requires touching the bead to turn it, hence the problem

I did search before posting, in fact I spent nearly two hours trying to find anything on this, and saw nothing relating specifically to my issue of how to hold the beads during the process. I’ve watched all of the tutorials I can access that are relevant to finishes, that’s how I got here. As I said initially I understand that sanding/buffing can produce a glossy finish without varnish, but I’m talking about the times when I do need varnish. Extensive sanding/buffing is also not easy for me as I have a disability that affects my joints and hand function, and that kind of repetitive motion can be a danger to me (and I do not have the money to invest in the machines referenced).

Hi Jen, Sorry I was not able to get to your question sooner (was busy with Easter) but it looks like Jocelyn has come in to try and answer it. Getting a high gloss finish on small round beads is tricky, as you are finding out. You can try and dip them, but then you have to fuss with the drips and trying to prevent the gloss from pooling on one side. You can brush them but you get lines and seams if you only coat them on one side at a time. One thing you can try is sticking them on a tapered toothpick. You can then hold the toothpick in one hand and brush the entire bead with the other… then stick it into a block of foam to dry. This can be a little time consuming but it is worth it to not have to deal with the seams.

I like to use a rock tumbler to do many beads at once, but of course the substrate I recommend and the tumbler will cost some money. It is something that will help you do larger batches and since the substrate will basically never wear out, the cost is minimal compared to something like the JoolTool.

I hope that helped you at least a little bit. Perhaps since your hands make it more difficult to work with the smaller bead shapes, you may consider making larger beads that are easier to sand or using techniques that don’t require the same kind of sanding methods, such as sculpted beads. There are lots of tutorials here that don’t need to be sanded at all.

Good luck and let us know if you need any more help!

LOL! Another tip I have seen used to steady beads on wire for one stop finishing is to use a large needle, pin or needle tool inserted slightly inside the hole.

All best, Jen…..

I’ve been making a ton of polymer clay beads and now I’ve run into a problem. How do I put varnish on a spherical or bicone bead without leaving fingerprints?! I stretched wire across a baking pan with the beads strung on the wire, but quickly realized that in order to get the entire bead coated I still have to use my fingers to spin it on the wire. What other technique could I try that won’t leave fingerprints? I know doing better/more sanding and buffing would reduce the need for varnish but I want to try using embellishments like mica powders and pastels and such, and would prefer a glaze over top to seal that in. I’m currently using Liquitex gloss medium and am pleased with it, except the fingerprints. The only workaround I’ve figured out is to only brush it on half the bead at a time, but then I’m getting a “seam” where those two applications overlap. Surely there’s a way to do the whole bead at once!

Quick update: I just examined the beads I varnished yesterday and many of them do have that visible ridge where the varnish overlaps. I dipped a few pendants I made from big lentil beads and that looks fabulous, but I’m having a hard time envisioning an efficient dipping method when we’re talking 20… or 50, I *told* you I was really getting into this… beads in a batch. So my initial problem/question stands. Really hoping people have some ideas. Thanks!

Hi Cindy,

I have researched many different varnishes and glazes about 20 different kinds to be exact. I have found that the water based glazes seem to work the best and don’t become gummy. I live in a part of the U.S. where the temperature is warm and dry most of the year so this helps with how well these products cure/dry. There is an item that I have not heard to mention that works wonderful on polymer clay. It’s called Liquitex Pouring Medium. It leaves a wonderful shine, but may need to be put on in several coats to get the effect desired. I would love to see you give this a try. I often enjoy going to different mediums to find new products I can use with polymer clay. Let me know what you think. Take care, Dee

The pouring medium sounds interesting Dee. I too like to look for things outside the norm… that is how you find the best solutions. I will keep an eye out for it. I bet they have in it the art store… I haven’t seen it in my Michaels. Thanks for passing that along!

Hi, due to polymer clay is hard to find here is Qatar, I’am planning to make home-made clay, air dry or porcelain and salted clay. Which is better that will last? I will make figure for ref magnet.

Thanks

Maricar

Hi Maicar, I am not that familiar with the clays that you mentioned, so I am afraid I can’t give you any advice on which will last longer for you. Perhaps someone else here knows?

Hello Cindy, I think that Miricar is talking about cold porcelain and the salted clay is made from flour and salt.

Hello Diana… yes it has been a looonnnggg time… great to hear from you! And a Happy (Early) Birthday to you :-)

In regards to your questions about the new site… yes the prices will be going up when we finally do launch (we are running a bit behind schedule). But anyone who is subscribed before the transition will definitively have an advantage. The current subscription price is still the same as when you were last around… 4 years ago.

Here is the link where you can set up a new subscription account if you like… Become A Member

.

Hi Cindy!

Haven’t been on here for quite a while. Unfortunately, someone (spawned) by the devil, had hacked my computer a while back. I lost everything! Which means that I have to start from scratch. I was with your original group in the beginning. I’m not completely computer literate, so from the start — had to bombard you with questions.

Happened to notice that you and your sweetie (Doug) are revamping a new web format. Unfortunately, my computer volume is not currently functioning at all, so I have to speak with my daughter to help me with it — then, I can hear what you are saying Ha! Ha! In the meantime, i have a few questions to direct to you: 1. What is the cost for this new website, and is it monthly?

2. Will the price change once it’s up and running? Thanks so much for your response. I sure did enjoy your teaching! Looking forward to hearing from you again,

Regards,and I know that this new format will be the best!

Diana Souza-Castro (MERMAID)

p.s. I am ready to celebrate my B’day on October 14th, and will be 71 years young. Amen! Hellooooo!

p.p.s. Sorry for my confusion, but an old “Carol Burnett Show” came on, and they are absolutely out of their gourdes! My concentration has gone out the window. Ha! Ha! What would we do without humor!!!

I signed up but need some assistance… help please

Hi Kathay – helping you with log-in issues is best done privately via email since it involves discussing username and password information. I just sent you an email message that you can respond to if you still need assistance.

And… welcome to to community :-)

Hi Cindy and Doug,

I was told you could use Armoral on polymer clay as a finish is this true? I need to put a finish that will cover over a large glitter without knocking it off…..

also I want to sign up for a year how do I do this can you send me the form…Kathay

Hi Kathay, I have not tied it yet, but I have heard that ArmorAll works great as a mold release on polymer clay but since it is just a lubricant, I can’t see how it would be a finish that would seal in glitter. Resin would work well or a couple coats of Varathane. Type “finishes” or “glazes” into the search box and you will find more info that will be helpful you.

As far as signing up for a year, here is the link to the page where you can do that… Polymer Clay Tutor Annual Membership

I look forward to see you over in the members library :-)

(Winsor & Newton Galeria, Varnish, Gloss Finish, Acrylic Paint Medium )

Can I use it with polymer clay I want it hard , shiny

And how to know the right and suitable wax for polymer clay I can’t find brands you talk about here in my country

I use fimo varnish now it need a lot of layer and it isn’t shiny enough for me

Hi Sheba, I have not tried that brand on polymer clay yet. The only thing I can suggest is to test it on a sample that you leave sit for a couple of months to see how it works. If it doesn’t get sticky over time, and it is shiny enough for you, you can use it on your projects. Hopefully someone else will have tested out and will know the answer for you. Good luck! Let us know how it works out, if you do try it…

Hi Cindy,

Where did you get your pink UV light….I have one but yours looks bigger and the bottom comes off….

I got it from Terry Morris at EpoxyJewelry (tell him I sent you :-) … not sure if he still carries it in pink.

I have three questions. I have been using 3d crystal lacquer on some of my polymer clay, because I wanted it to be shiny and didn’t know you could sand it to make it shiny. Anyway, some of those pieces have gotten sticky, and some haven’t. For those that have, do you know of any way to fix the problem?

Second question is relating to a comment you made about baking for an extended amount of time to make your pieces shiny without glazing. How long exactly? And what temp?

Last question is about textures pieces. I like to use a lot of texture in my pieces, and I find that sanding doesn’t really work. Either I sand the texture away, or the piece just gets shiny in the raised areas, and the rest of it is dull. Do you have a solution for this? Thanks

Hannah

Hi Hannah!

All of your questions are answered on this site and available by entering “question” in the search box in the upper left. Tons of tutes, videos, blogs and especially, the comments, answer each and every one of the issues you have noted.

I’d try “sanding,” “shiny buffing,” “sticky finish,” “baking,” and “finishing textures.”

It’s a quick and easy way to learn, and fun to find the answers.

If you need more help, come back, and plenty of folks here will help you out.

All best, and have fun!

Jocelyn

If you google polymer food safety here, there is a ton of stuff. My opinion is no.

Hi Cindy,

I was asked a question I don’t know how to answer so I thought you would know….If you make a bowl out of polymer clay can you put food in it?

Kathay

HI Kathay, you can’t put food directly on polymer clay, so if you want to make a bowl to put food in, you’ll have to have the polymer clay on the outside of a glass or wood bowl, that is food safe.

Hi Cindy, I have recently become interested in making polymer clay jewelry. I have done tons of research and Varathane water based crystal clear polyurethane [no odor] seems to be very popular to seal polymer clay projects… I went to home depot yesterday and purchased Varathane TRIPLE THICK water based polyurethane because I didn’t realize there was more than one type of water based Varathane until I got home (although that was the only kind they had anyway)… Do you know if this is still something that would work for jewelry making? I don’t want it to look globby or cloudy or to feel sticky over time obviously.. I also don’t want to stink up the house (I haven’t opened it because I’m thinking I might just return it). Let me know if you have any experience/knowledge of this particular polyurethane – it’s the one in the red and white container. Thanks!

Hi Jessica, I actually have never heard of that particular kind of Varathane, so I’m afraid I can’t give you any advice. Perhaps someone else here has tried it?

I put on as you put it my lab coat and tried it on a scrap piece….it does work but it darkens the Magic glos it gives it a vintage look…I would like to see if you have better luck….

What else can I use my UV light for besides Magic glos?

thanks Cindy…..

You can use it to cure UV nail Gel and to make Photopolymer plates (your own rubber stamps). You can also cure my favorite brand of UV Resin called UltraDome from Terry Morris at EpoxyJewelry (tell I sent you :-).

I am not sure if this was answered or not…After you use magic glos on cured clay can you put a border of raw clay around the cured piece of clay you already put magic glos on and put it back in your oven without harming the cured magic gloss. I hoped you understand what I am asking.

Hi Kathay, now I haven’t done this yet myself, but I did read that Magic Glos is safe to bake in the oven after it has been added to a polymer clay piece and been cured. So your idea of adding a clay frame around your piece should work. If you really love your piece and are afraid of experimenting on it, I would test it on a small sample first though. I need to add Magic Glos to my list for the test lab, and I could add that test as well. Until then, you should put on your lab coat, and try it out yourself. :) DO let us know what happens when you do, OK?

Hello again I just did what u said and I let dries (I dipped it and let it set for 5 whole days ) then I tried to scratch it and it peeled again why is that it makes me really mad ) and I peeled it off completely then I applied it with brush this time a very thin layer and I let it set for one day and half and I scratched it and it peeled again so why is that please help me this is my second charm that is ruined because of the duraclear varnish any one has experienced this? ????

Hi Boboosy, I am sorry to hear you are having such trouble. I am wondering if the coating is maybe too thick and the outside of the finish is curing hard before the inside gets a chance to and is still soft underneath. This might make the finish separate form the piece. Also, you mentioned Duraclear… I have never used that before so I am not sure if that is the problem or not. Maybe someone else here has tried it before?

Hello Cindy, first of all thank u for helping me and the others I’m big fan ???? so I wanted to ask you if I can use resin to glaze my polymer clay charms? And one more question I once used duraclear varnish as many other polymer clayers said it was good and durable so I glazed my charm 1 layer and let it sets for about 20 minutes then applied another coat then I let it sets to the day after .when I used the charm as pencilcase chain the day after it peeled and get scratched so why is that? And I used duraclear also on another 2 charms 1 layer only and i let it sets the whole day or 2 days without touching it or adding another layer so after my damaged charm peeled off I went to home and scratched the other two charms and nothing did happend i tried to scratch it many time but again nothing did happen it didn’t get scratched or anything so what the matter with the damaged charm?? please help me I really am sad about what happend to my charm : ‘(

Hi boboosy, sorry to hear about your damaged charm. It sounds like you didn’t let the first layer dry properly before putting on the second layer.

Let me explain… the first layer went on and started to dry a little on the outside but was still wet underneath. Then the second layer went on top. The second layer could dry, because it was close to the air, but the first layer was trapped underneath the second and couldn’t dry out. Because that first layer never hardened to the clay, it peeled off really easily… especially with the thick crusty layer on top.

On the piece with only one layer, it got a chance to get totally hard and bond to the clay. That is why it was so tough compared to the two layer one.

See if you can remove the ruined finish by soaking it in rubbing alcohol and scrubbing with a tooth brush.

Then when all the old finish is gone, try coating it again. This time if you want to add two coats, let it dry for a few hours before adding the second layer.

Hope that helps!

Thank u so much I will definitely follow ur instructions and let u know about the results thanks so much again ????

Hi Cindy,

I just came upon your videos tonight. Even though I have been working with polymer clay for years, I think you are amazing and wish I heard of you years ago when I was first starting out.

I have a couple questions for you.

I advertise my jewelry products as vegan, but I use diamond varathane because it’s the top rated varnish for polymer clay; however, something tells me that varathane is NOT vegan. I can’t seem to find anything in my research denying my claim; therefore, I would like to go without using varnish on my pieces. The problem is my pieces don’t seem “finished” if I don’t use a varnish of sorts, and I worry they won’t be protected from scratches over time. Do you have any suggestions about this? Do you varnish all or most of your pieces?

I am still new to sanding and buffing my pieces; but I find that when I start at 320 grit and work my way up to 1000, I can still see tiny scratches in the clay from the sandpaper I used. I start at 320 to try and remove any flaws or imperfections in the clay. I wonder what I’m doing wrong. When I sand I use it with water, so I’m not sure why these scratches occur.

Any advice would be greatly appreciated, Cindy.

Angela

Hi Angela, glad you like this site! As far as finishes goes, I prefer to use Renaissance Wax after sanding and buffing my pieces. It is made with a petroleum product so I don’t know if it qualifies as Vegan or not. (Does polymer clay?)

With the sanding, each grit works by scratching finer and finer lines until they are so fine that you can’t see them anymore. If your scratches are still there, then you are either starting with too coarse a grit (I usually start with 400 rather than 320 unless I want to remove a lot of clay.) or you are not sanding long enough with the next grit to remove the fatter scratches from the previous grit. (Hope that makes sense.)

Basically, start at 400grit and sand longer at each grit. You shouldn’t see any scratches when you are done.

To learn more about any of these topics, use the search box to find more articles/videos on what you need. Good luck!

I just started using MinWax PolyUrethane, which I really like, but the cleanup is mineral spirits. (I’ve also discovered that nail polish remover will clean the brush, and I think ammonia will also.) It isn’t the oil modified one, it’s not the one for floors, it’s the fast drying one in the brown can, so I thought I was okay. I’ve tried Polycrylic and was dissatisfied. I’ve tried a lot of others too, and although I like Future’s finish, I have a great deal of difficulty with the odor (Mod Podge is banned from my house because of the odor and Future is close to being banned).

If this PolyUrethane is also not good for polymer clay, there’s another one I’m going to try, MinWax Express Clear, which comes in a tube. I really hate the idea of this PolyUrethane not being okay… how do I tell? I was going to use Varnish – the actual product that cleans up with mineral spirits because it does a nice job, but if it eats the clay…

Thanks,

Martha

Hi Martha, I am currently testing what I believe to be the same product as yours, though in the fine print on the back it does say it is oil based, so I am not sure. Any way, it appears to be doing very well on polymer clay, but I haven’t let it sit long enough yet to be sure. I will be doing a PcT Test Lab video on it, when I am sure it has sat for long enough. Thanks for your comment!

Cindy your advice as always in invaluable. I get frustrated because I sand and polish by hand and I just cant get things to be as shiney as I want at time. I love the verathane and the future they are now my always go to varnishes. My issue is streaking. I sand and buff all my pieces but I still find that the varnish is streaky at times. DO you suggest more thing coats and opposed to a thicker coat? and also what kind of paint brush would you recommend? I always wondered if it was the synthetic brushes I was using. Again thank you for your advice

isabelle

Hi Isabelle, when it comes to finishes, it is always better to do a few thin coats than one thick coat. This way the layers will properly dry underneath. As far as streaking goes, that happen because of three things. 1) Varnish not mixed properly 2) Dirty brush 3) Scrappy quality brush. The best brushes for acrylic paints and varnishes are synthetic bristles. Get a good quality varnish brush, clean it properly and you will have the brush for years. Go to the artist paint section of your craft store and you should be able to find something suitable there. Good luck!

Love your tutorials!

How do I keep my charms clean after they have been glazed with polyurethane gloss and finished with quick shine floor finish? My white polymer charms are getting very smudged and I don’t know how to remedy the problem.

-Rachel

Hi Rachel, it sounds like you may be having some compatibility issues by using more than one type of finish on your polymer clay charms. My guess is that they are actually getting sticky and that is why they are getting smudged looking. Remove both finishes with rubbing alcohol and then add a polymer clay safe finish (do a search on this blog at the top of the page) and decide on which finish you would prefer to use. There are several choices in addition to the Varathane mentioned in the above article. That should keep your pieces clean looking and not smudged or dirty. Good luck!

Hi! I make pendants out of polymer clay and then paint them with acrylic paint. I went to the store to buy varathane as a glaze (everything else I tried got sticky in the sun) and on the bottle it says not to let it touch skin. This is a problem since I’m making necklaces! Do you have any suggestions? Thanks!

Hi Anna, that is interesting… I have never heard of the packaging on the Varathane saying that it shouldn’t be against the skin. That must be a new addition. If that is the case then I would avoid using it for jewelry. My new favorite finish for polymer clay is Renaissance Wax. It is way easier to use, leaves a lovely sheen, has UV protection, resists oils and diets and works wonderfully on jewelry. I have done a demo of it. Check it out. I think you will like it best as well… Renaissance Wax Demo

To Cindy Lietz

I appreciate all the help you give your fans ….. I noticed your last comment was in Sept-2012 . Have you used or heard of a site that still sells

the original Future floor polish ? I also wanted to know why my first piece of

sculpey original clay / over a china doll head/ still has a sticky place on it. I called the instructor of the class , and she said to add more gesso to it , to help seal it. I even stuck it outside to dry, and it still has a sticky spot . What do you recommend ?

Thanks for your help …. S.A.

Hi Susan, thanks for your comment! It sounds like you are having an incompatibility issue with the finishes on your doll. Adding more gesso will just make it worse. You will need to remove the old finishes if you can, with some rubbing alcohol or acetone. Once your piece is clean and you have removed the sticky finish, then you can consider adding a new finish to the clay. If you don’t remove the old stuff, the stickiness will just work it’s way to the surface and cause you more problems down the road.

As far as sites that still sell Future, I don’t know about that. Maybe Amazon? I wouldn’t bother trying to find it though. There are much better finishes than that now. My favorite finish now is Renaissance Wax. It will give you a beautiful smooth sheen and is wonderful for protecting your pieces from dirt, oils and UV rays.

If you need more info, use the search box at the top of the page.

I have used it and loved it at first until I noticed later that it turned a hideous shade of yellow. I wrote to them since it said it was non-yellowing on the bottle and they said you had to use all their materials for it not to turn yellow. (This was not stated anywhere on the bottle.) Anyway, I quit using it. However I did use it on bread clay jewelry and they said maybe something in the glue or bread made it turn yellow. I don’t know about that but if you want to try it, I would do one piece and let it set a year and see how it looks then.

Has anyone used DecoArt Triple Thick gloss. They have it for a very reasonable price on Amazon, but I am hesitant. Have checked several places here on the blog, but only find a mention here and there.

Hi Cindy! My name is Jackie and I have a somewhat difficult question that I was hoping you could help me with. My boyfriend has been making gauged plugs (for stretched ears) with polymer clay. He is using Sculpey III polymer clay and Sculpey Satin Glaze. When he first started making them, he made a couple for himself to test them out. After taking them out at the end of the day, we noticed that there is a temporary white ring around the plugs where they were resting in his ears.The ring goes away after a little while and there is no discoloration on the plugs. We have conluded that this is some sort of reaction between the glaze and/or clay and the oils in his ear. Because it is temporary, it does not seem like that big of a deal. Unfortunately, it seems a bit unprofessional since we are trying to make the plugs to sell them. Also, we want our products to be 100% safe and we don’t feel completely safe about what may be going into the body since the reaction is occuring. I was hoping that you may have some insight about a product that we could use that would negate this problem and be safe. I know this is a somewhat unusual question since this is not something most people make, but I’m really hoping that you may be able to point me in the right direction. We have seen other plugs for sell that were made with polymer clay and, from what I can tell, do not have this problem. I have searched the internet for information about this and can’t really seem to find anything. I would really appreciate any help or advice you could send my way. Thank you very much and I look forward to hearing from you soon!

Jackie,

Have you tried any of the other finishes discussed

in this stream of comments or on this web site? I

used Sculpey Glossy Glaze and have not had similar

results but I can’t think of anything I’ve done that is

in constant contact with skin.

I think using Future floor finish might be the

least expensive thing to try. You can find it at

Walmart for around $6 or so. I think they may even

have small cans of Varathane available now, whereas

in the past, you had to buy a pretty large can to

even try it out.

Good luck,

Jan

Hi Jackie, sorry to take so long to get to your question. We have been on the road on our first Polymer Clay Tutor Roadtrip, so I haven’t been able to respond as quickly as usual.

As you may have gathered from looking around this site, I am not exactly a gauge wearer, so I can’t attest to knowing the best info on the subject firsthand. However, in my internet travels, I remember coming across across someone who claimed to know a lot about the subject and who had a strong opinion that wearing polymer clay directly in your ears, especially during the stretching phase of plug wearing, is a very bad thing to do, with or without a finish.

hi dear! can you help me please! I live in France I can nor buy the product to finish clay,I mean Varathane product,I tried to buy online with ebay and amazon all of them do not ship to France.I found some similar product ,can I use that for clay?that product is vernis brillant reflet a France product,it use for wood.thank you

Oanh that is the kind of question that is impossible for me to answer, since I can’t try the product myself. Maybe someone else from France can help you. The one way you can tell whether a product will be compatible or not, it to make a sample and test it on it. Make sure to make note on when you started you test, and then wait for several weeks or months to see if the product stays good and dry, or if it becomes sticky over time. Do let us know how it goes. We have several students/readers from France and your tests would be helpful to them. Good luck!

hello I was wondering if it was safe to use acrylic paint on figures when using this finish. Will the paint crack or chip like the new sculpy formula does?

Hi there…

it won’t crack if you use a sealer like pledge wipe & shine or pledge future polish.

(“,)